Yongbo Plastic Products Co., Ltd., located in Zhongshan City, Guangdong Province, is a well-established company specializing in the production and development of plastic and foam products. Their products are widely used in packaging molded foam items, and they have become a leading supplier of foam packaging solutions in the northern region of Zhongshan.

Introduction to Injection Molding Machines in the Foam Industry

An injection molding machine—also known as a plastic injection machine—is used to form various plastic products by injecting molten plastic into molds. It is an essential piece of equipment for creating plastic products from thermoplastic or thermosetting materials.

How Injection Molding Works:

The injection molding process involves using the thrust from a screw (or plunger) to inject molten plastic into a closed mold. The plastic solidifies, taking the shape of the mold, and after cooling, the final product is ejected. The process is cyclical, with the following key steps:

- Material feeding

- Melting and plasticizing

- Injection and pressurization

- Cooling

- Ejection of the product

The Role of Foam Machines in Plastic Production

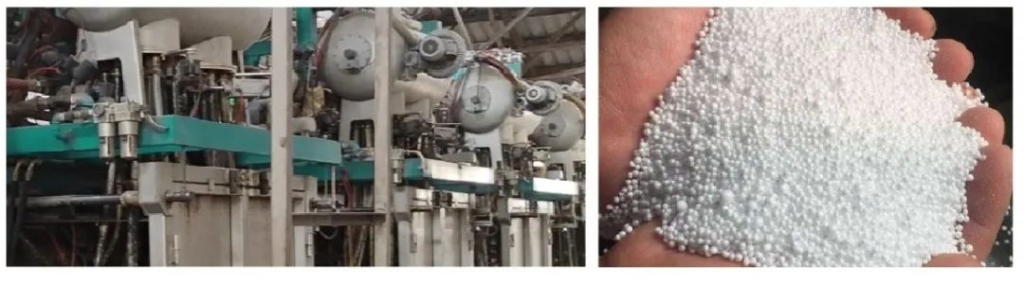

In foam production, machines like the polystyrene foam machine (also known as the polystyrene foaming machine) are critical. These machines use a screw-driven mechanism to generate pressure, which forms foam materials.

Foaming Principle:

At room temperature, raw materials are softened by strong solvents, creating the necessary conditions for foaming agents like butane, pentane, and petroleum ether to expand. Under pressure, the foaming agents vaporize, causing the softened raw materials to expand and form foam. Maintaining the right pressure is key to achieving consistent foaming.

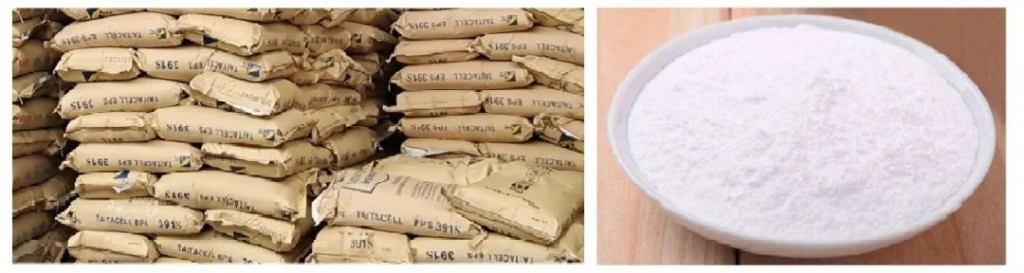

Before foaming (raw foam particles)

After foaming (steamed foam particles)

Machine-extruded foam

Finished foam products ready for shipment

Energy Efficiency in the Injection and Foam Industry

In both injection molding and foam production, ضواغط الهواء are a vital part of the manufacturing process. Air compressors can account for up to 40% of the total energy consumption in injection molding, and up to 70% in foam production. Therefore, selecting energy-efficient, eco-friendly, and quiet air compressors is crucial for reducing operational costs and minimizing environmental impact.

Yongbo’s Partnership with Baldor: A Game-Changer for Energy Efficiency

Yongbo Plastic Products partnered with Baldor to implement a BD-125LPM low-pressure permanent magnet variable frequency air compressor. This solution has ensured a stable and continuous air supply throughout their production process, significantly reducing energy consumption while maintaining reliable compressed air for their operations.

Energy Savings with Baldor’s Compressor:

Before implementing Baldor’s energy-efficient air compressor, Yongbo’s monthly electricity bill for production was around 75,000 kWh. After switching to Baldor’s low-pressure permanent magnet compressor, their monthly consumption dropped to approximately 60,000 kWh, while maintaining the same production capacity.

Customer Testimonial:

Mr. Li, General Manager of Yongbo Plastic Products, shared his positive experience with Baldor’s compressors. During his visit to Baldor’s factory, he was impressed by the energy-efficient and silent operation of the compressors. He particularly appreciated the ability to remotely monitor and control the air compressor’s performance via his mobile phone. Mr. Li has since recommended Baldor’s solutions to many others.

Mr. Li – Baldor’s Energy Efficiency Ambassador

Baldor’s Commitment to Sustainable and Efficient Solutions

Baldor continues to support its customers with energy-efficient, high-performance, and reliable air compressor solutions. With continuous improvements in system integration, monitoring, and control, Baldor is committed to delivering smarter and more sustainable solutions for the manufacturing sector.

For more information about energy-efficient air compressors, visit our product page.