Everything You Need to Know About Centrifugal Air Compressors

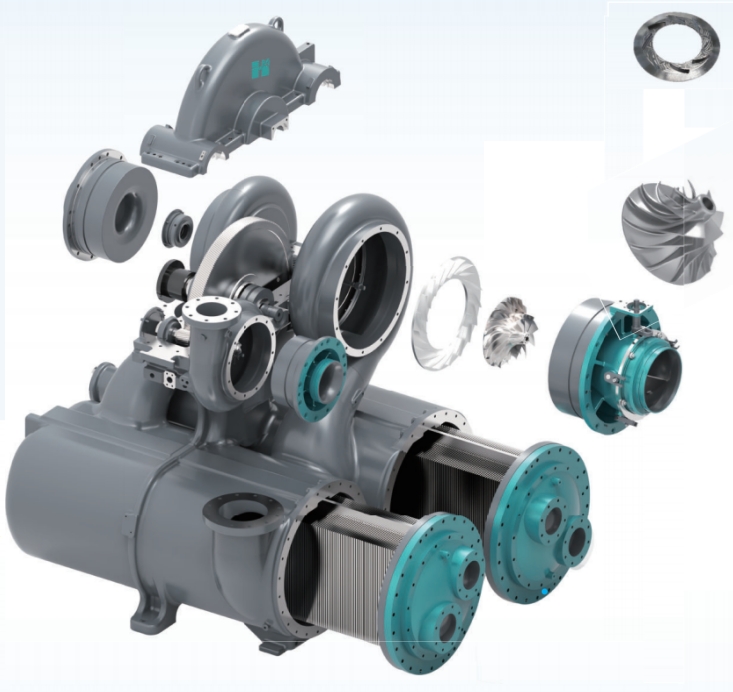

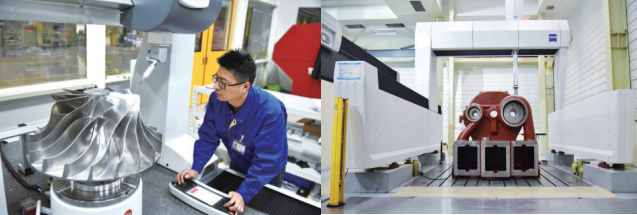

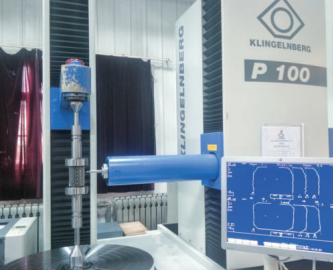

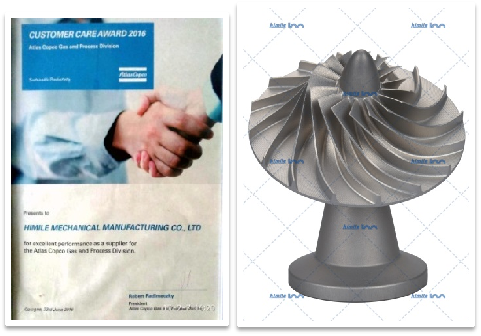

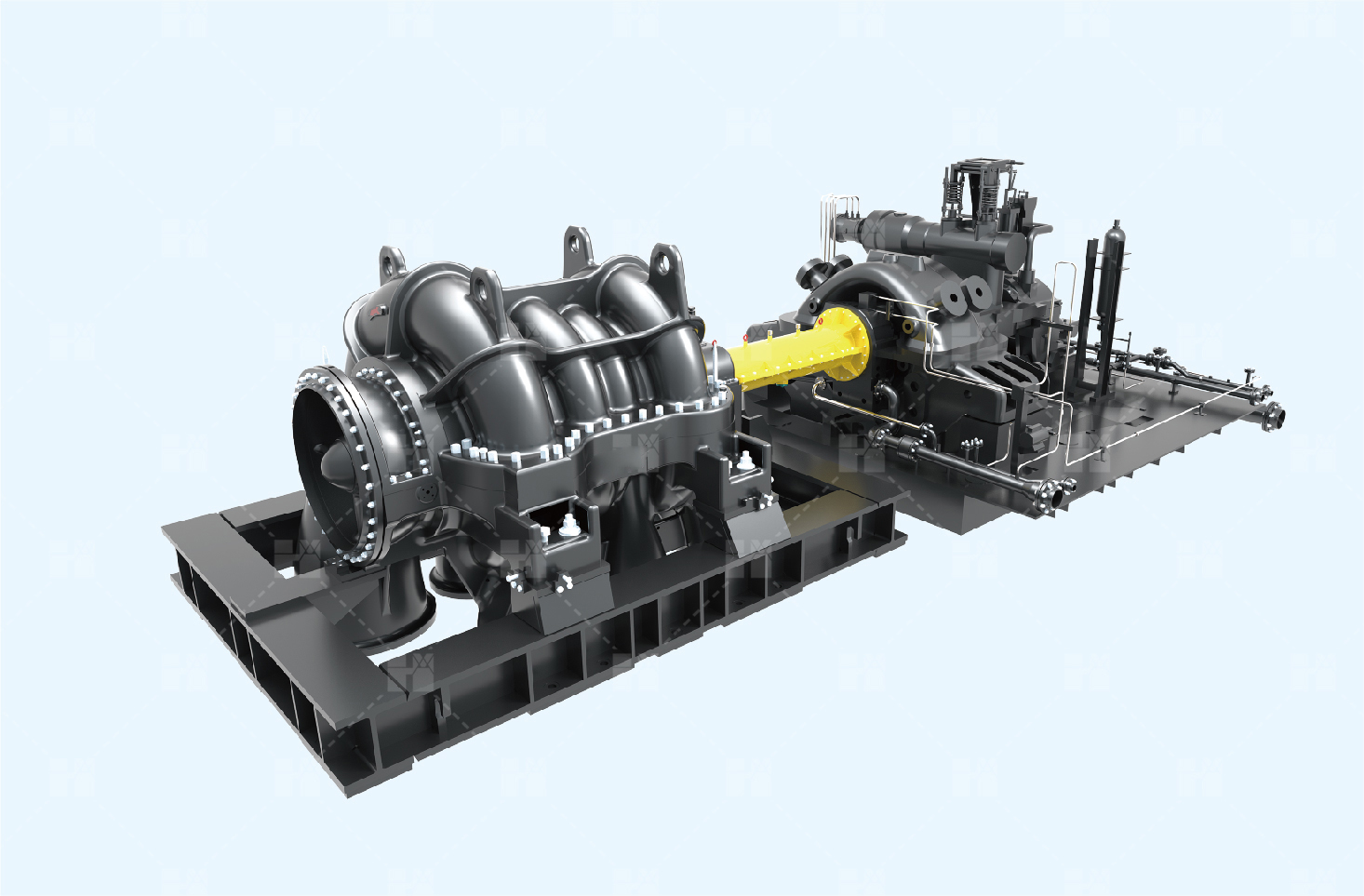

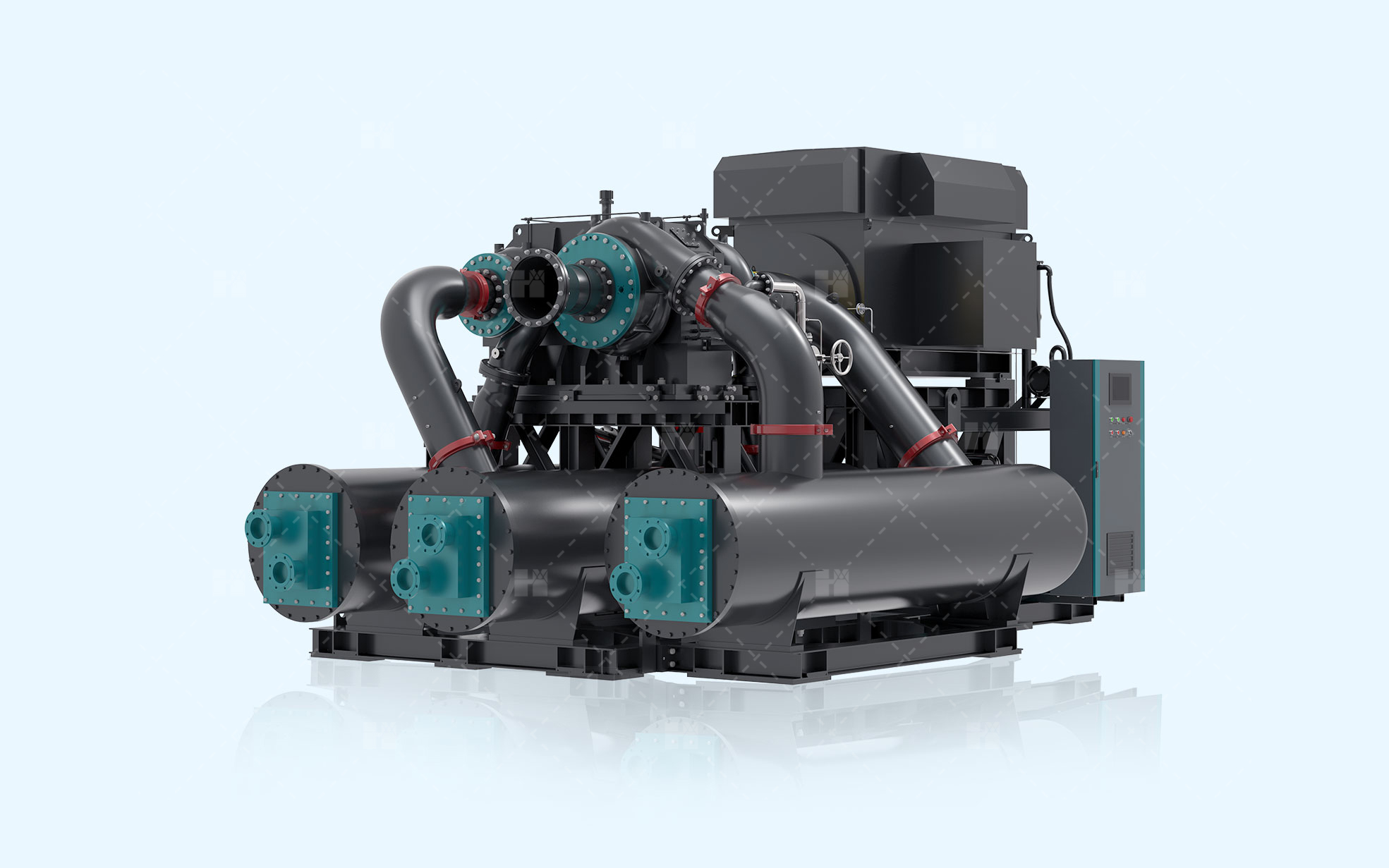

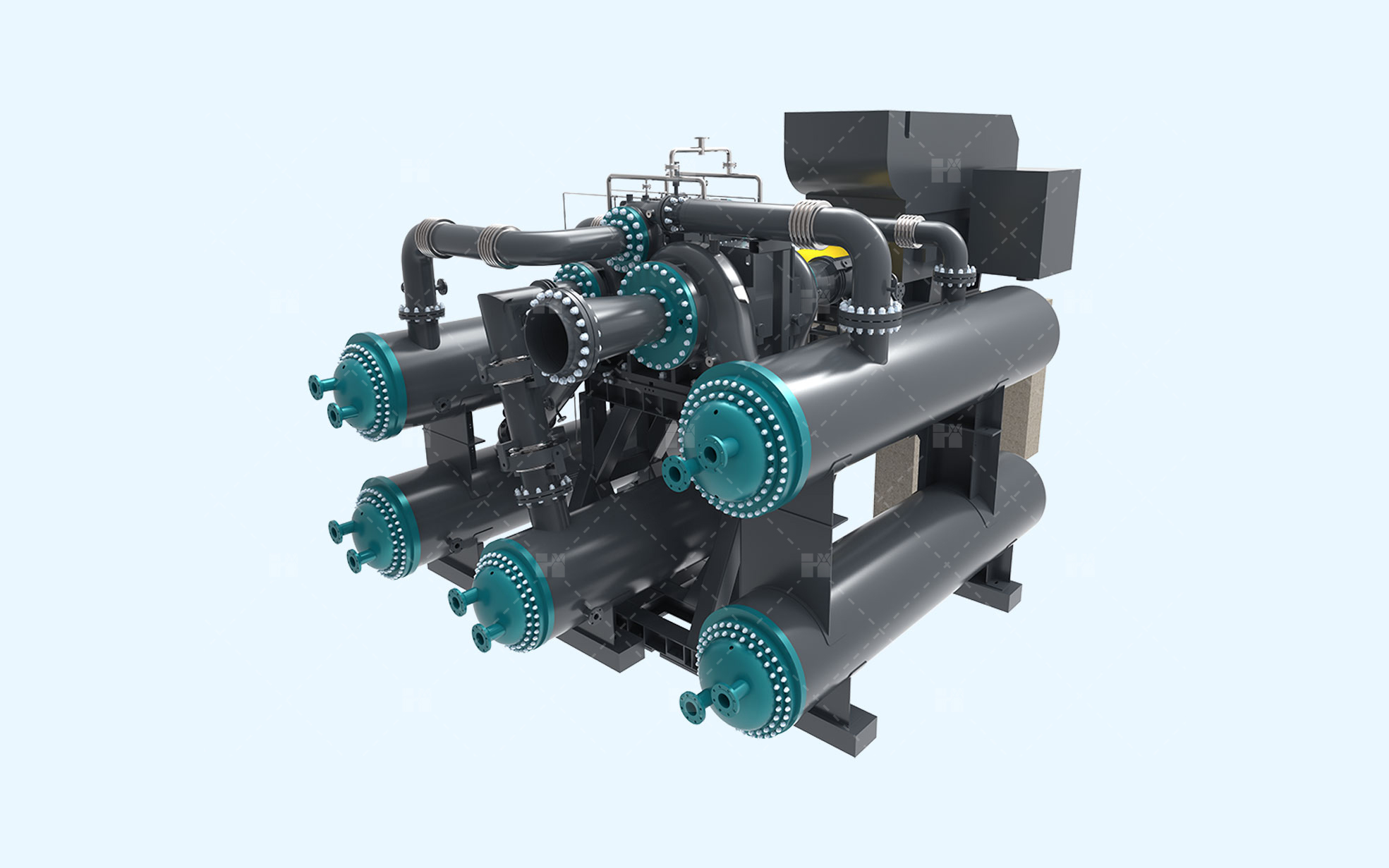

Centrifugal air compressors use high-speed rotating impellers to convert kinetic energy into pressure energy. Known for their oil-free operation, high efficiency, and large capacity, these compressors are widely used in industries like power generation, chemical processing, and air separation.