Selecting the correct air compressor pressure is essential for efficient operation, tool performance, and long-term equipment reliability. Whether you’re working in automotive, woodworking, metal fabrication, or industrial manufacturing, understanding the relationship between pressure (bar/psi) و airflow (CFM/m³/min) ensures that your air compressor delivers consistent results.

Why Correct Air Compressor Sizing Matters

An air compressor that doesn’t match your system’s requirements can create significant problems:

- Undersized compressors lead to pressure drops, reduced tool performance, and unnecessary downtime.

- Oversized compressors waste energy, increase operating costs, and cause excessive wear on components.

Choosing the right pressure and airflow ensures:

- Optimal tool efficiency and higher productivity

- Longer service life for tools and compressors

- Reduced energy consumption and maintenance costs

Pressure by Application

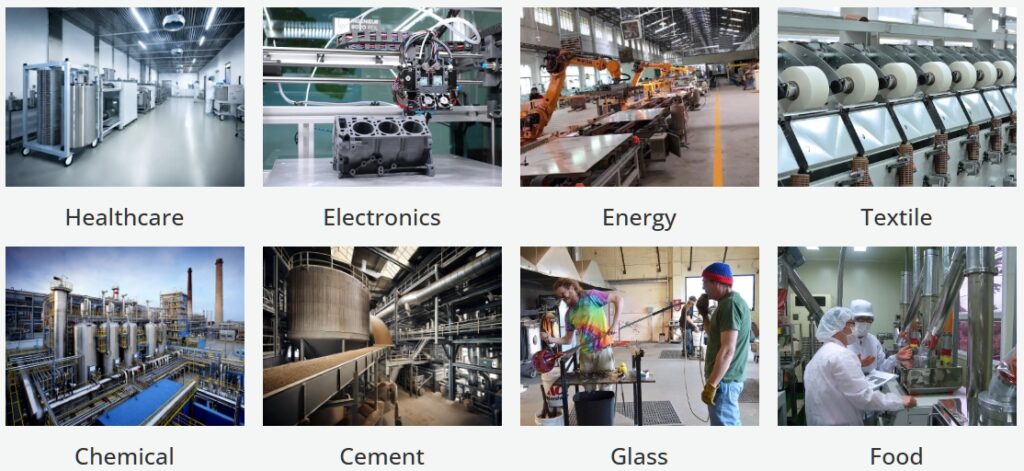

Each industry has unique air pressure requirements based on its processes and standards. Using the correct settings not only improves efficiency but also extends the life of your equipment. Typical examples include:

- Textile Industry: Generally operates at 6–7 bar (90–100 psi) for spinning, weaving, and pneumatic controls to maintain consistent production quality.

- Food & Beverage: Requires 6–8 bar (90–120 psi) depending on packaging, bottling, and conveying applications. Oil-free systems are commonly used to meet hygiene standards.

- Energy Sector (Oil & Gas): Heavy-duty operations, such as drilling or pipeline controls, often need 8–10 bar (120–150 psi) for maximum reliability in harsh conditions.

- Automotive Manufacturing: Typically runs at 6–8 bar (90–120 psi) to power assembly lines, painting systems, and pneumatic tools for high-volume production.

- Pharmaceutical: Operates at 6–7 bar (90–100 psi) to supply clean, dry air for mixing, coating, and packaging processes while meeting regulatory requirements.

- Metal Fabrication: Uses 6–8 bar (90–120 psi) for cutting, welding, and grinding, ensuring stable performance in demanding environments.

- Paper & Printing: Runs at 6–7 bar (90–100 psi) for presses and finishing equipment, maintaining precision and reducing downtime.

For airflow calculations in metric units, convert easily with our CFM to m³/min Conversion Tool.

By understanding these ranges and converting units as necessary, you can ensure your air compressor provides the precise pressure required for each task.

How to Calculate Air Compressor CFM (Airflow)

Pressure alone isn’t enough—your air compressor must deliver the right airflow (CFM or m³/min) to support continuous operation. Follow these steps:

Check Tool Specifications

Every pneumatic tool lists its required airflow. If specifications are in m³/min instead of CFM, use our CFM to m³/min Conversion Tool to avoid miscalculations.

Account for Multiple Tools

Add up the CFM of all tools running simultaneously. For example, three tools requiring 10 CFM each means your compressor should supply at least 30 CFM.

Include a Safety Margin

Add 25–30% additional capacity to accommodate pressure fluctuations and prevent compressor overload during peak usage.

Verify Pressure Ratings

Pair airflow calculations with pressure needs. Use the Bar to PSI Conversion Tool to match international specifications accurately.

Quick Reference by Industry:

| Industry | Typical Pressure (PSI) | Typical Airflow (CFM) |

| المنسوجات | 90–100 | 500–2,000+ |

| المأكولات والمشروبات | 60–120 | 200–1,500+ |

| Automotive Manufacturing | 90–120 | 1,000–5,000+ |

| الإلكترونيات | 80–100 | 100–800+ |

| Energy (Oil & Gas) | 100–150 | 2,000–10,000+ |

| Pharmaceutical | 80–100 | 300–1,200+ |

| Metal Fabrication | 90–120 | 1,000–4,000+ |

| Paper & Printing | 80–100 | 500–2,000+ |

Converting Units for Accurate Sizing

For global operations, you may need to convert units to match international standards:

- Bar to PSI: Use our Bar to PSI Conversion Tool to switch between pressure units.

- CFM to m³/min: Use our CFM to m³/min Conversion Tool to size airflow requirements accurately.

The Right Air Compressor Pressure for Each Application

To maximize performance:

- Match both air pressure (bar/psi) و airflow (CFM/m³/min) to the application.

- Use reliable conversion tools to prevent errors in unit calculations.

- Select an air compressor designed to maintain required output consistently, even under demanding conditions.

By applying these practices, you’ll improve energy efficiency, extend equipment life, and achieve higher productivity across all operations.