1) Executive Summary

إن صمام التفريغ is a small, automatic device that vents residual air pressure when a compressor stops. By removing trapped pressure, it allows the motor to restart under low load, reducing electrical stress, shortening recovery time, and protecting components. In Baldor systems, a healthy unloader valve supports our goals of energy saving, uptime, and predictable operating costs.

2) What Is an Unloader Valve?

أن صمام التفريغ is a control element that opens briefly at shutdown to vent built-up air from the discharge side or short line between the pump and check valve. This ensures the next start happens against minimal back-pressure.

- Where it’s installed

- Compact units: integrated with or adjacent to the pressure switch; a small tube connects to the check valve.

- Larger systems: externally mounted و pilot-controlled based on pressure changes.

- Applies to

- Reciprocating (piston) compressors و الضواغط الحلزونية, with design details varying by model and control strategy.

3) How It Works (Cycle Overview)

- Running / Load: The compressor builds pressure; unloader valve is closed.

- Stop at Cut-out: The pressure switch turns the motor off; unloader valve opens to vent residual air.

- Restart at Cut-in: Pressure drops to the lower set-point; the switch turns on; unloader valve closes and the unit resumes compression.

4) Why It Matters for Reliability & Cost

- Easier Starts, Lower Inrush: Reduces torque demand and nuisance breaker trips.

- Stable Duty Cycles: Prevents false restarts and extends component life.

- Lower Total Cost of Ownership: Fewer start failures and less wear on starters, contactors, and seals.

- Energy Alignment: Works with Baldor’s energy-saving controls to minimize waste during cycling.

5) Common Failure Modes & Field Symptoms

| Condition | Field Symptom | What It Means |

|---|---|---|

| Stuck Closed | Motor struggles to start; high inrush; tripping | Residual pressure is not vented; starting against load |

| Stuck Open / Leaking | Can’t reach set pressure; constant hissing | Air is venting to atmosphere; chronic inefficiency |

| Intermittent | Unstable pressure; irregular cycling | Pilot/solenoid/pressure switch actuation is inconsistent |

6) Technician Maintenance Procedure (Baldor Best Practice)

Safety first: Lock-out/tag-out power, and fully depressurize the tank.

- Identify the assembly (integrated vs. external).

- Inspect & clean seat, spring, and small-bore lines; remove moisture, debris, or scale.

- Leak-test fittings and tubing; re-seal or torque per spec.

- Verify actuation: at cut-out, valve opens and vents; at cut-in, it closes cleanly.

- Replace if worn مع genuine Baldor components and proper thread sealant.

- Functional test across several cycles.

7) Integration with Baldor’s Energy-Efficient Ecosystem

Baldor combines high-efficiency air ends, intelligent controls, and robust after-sales support to reduce lifecycle costs. The unloader valve is a small but essential piece that enables optimal cycling, stable pressureو repeatable restarts—especially in variable-demand environments.

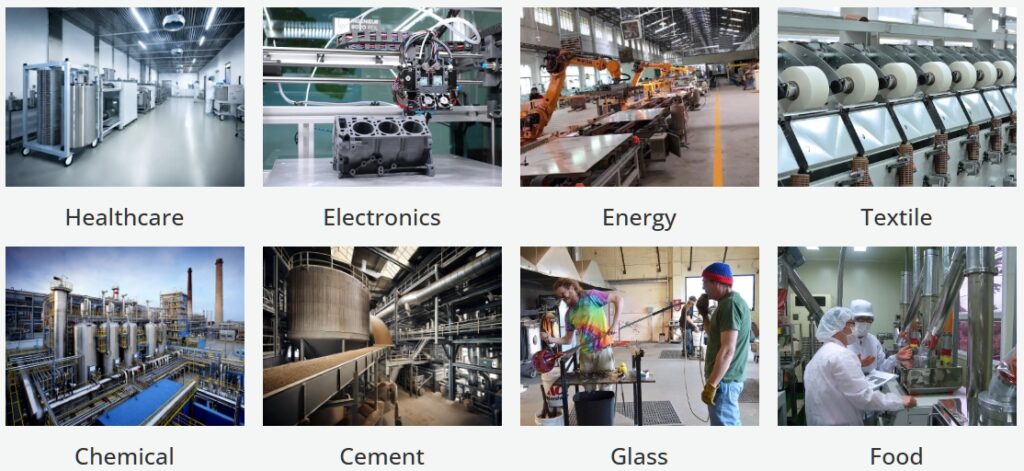

8) Selecting the Right Compressor

Whether you run compact piston units or heavy-duty screw systems, our team can specify the correct control strategy, pressure bands, and accessories for your duty cycle.

9) FAQs

Q1: Do all compressors use an unloader valve?

A: Reciprocating units rely on it for low-load restarts. Screw compressors also use unloading strategies, but the architecture differs by model.

Q2: How often should we check it?

A: Add it to quarterly PMs (or more frequently in dusty/moist conditions). Inspect seating, actuation, and leaks.

Q3: The unit won’t restart after stopping—what now?

A: Confirm power and pressure switch states; verify the unloader vents at cut-out and seals at cut-in. If symptoms persist, see the Load & Unload Troubleshooting guide or contact Baldor.