Laser cutting is one of the most versatile and widely adopted technologies in the manufacturing industry. From metal fabrication to automotive, aerospace, medical devices, and precision instruments, laser cutting machines are relied upon to deliver high-speed, high-accuracy cutting across various materials and complex geometries.

However, many don’t realize that compressed air plays a vital role in the laser cutting process—and the quality of that air directly impacts the machine’s performance and the final product quality.

What Role Does Compressed Air Play in Laser Cutting?

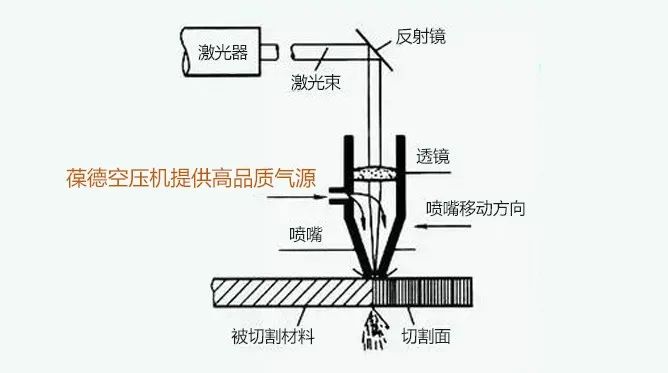

Compressed air serves as a critical auxiliary gas in laser cutting machines, fulfilling three primary functions:

- Delivers cutting gas to the laser head for clean and precise cuts.

- Powers the pneumatic system for the clamping mechanisms on the cutting table.

- Blows dust off the optical path to protect internal components and maintain accuracy.

Each of these functions ensures the laser cutting machine operates smoothly, efficiently, and without interruption.

How Air Quality Affects Laser Cutting Results

Poor-quality compressed air can cause serious issues in laser cutting operations. Moisture, oil, and particulates in the air supply can:

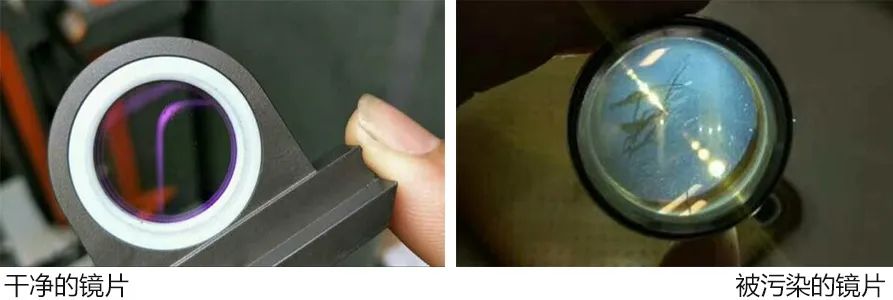

- Contaminate the protective lens of the laser head, affecting beam transmission.

- Cause laser focus distortion, leading to incomplete or low-quality cuts.

- Increase defect rates, machine downtime, and maintenance costs.

🔗 Explore our compressed air purification solutions

Damaged parts caused by poor air quality:

What Air Quality Standards Are Required for Laser Cutting?

To maintain optimal cutting performance, laser cutting systems require clean, dry, and oil-free compressed air. Here are the essential standards:

- Pressure Dew Point: 2–5°C

- Oil Content: ≤ 0.001 ppm

- Particle Filtration: ≤ 0.01 μm

Meeting these standards demands a high-performance air compression and treatment system.

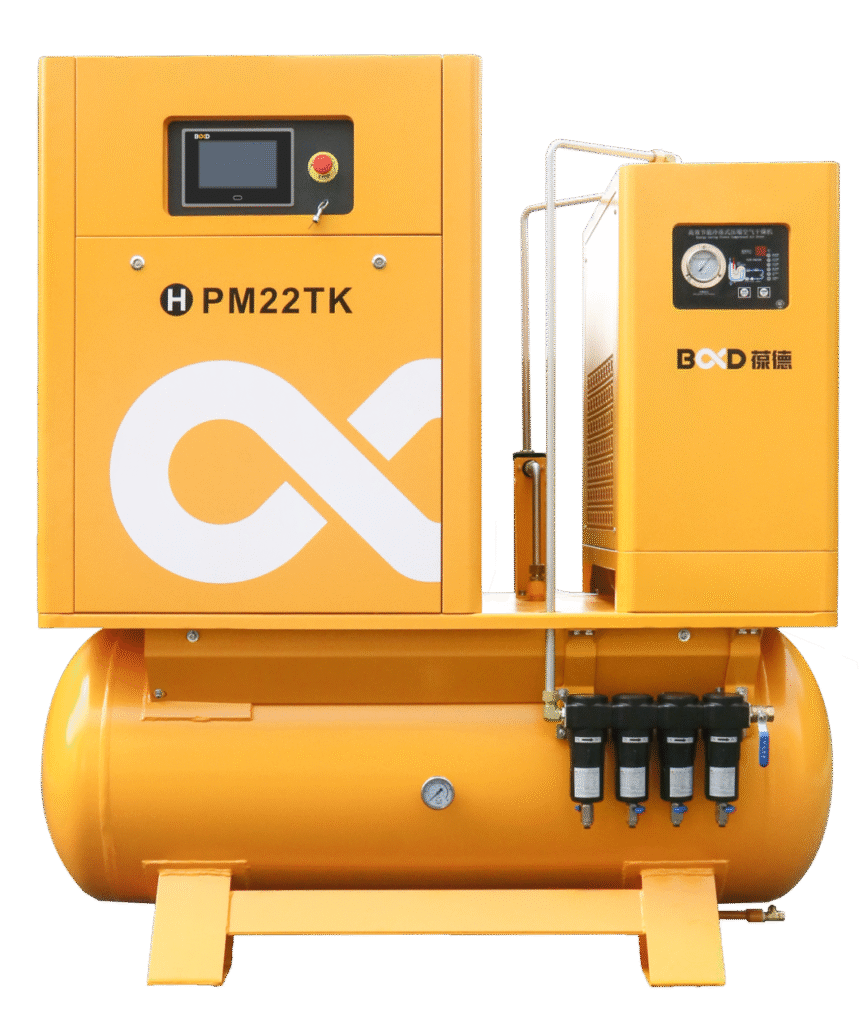

Baldor’s Laser Cutting Dedicated Air Compressor System

To address these challenges, Baldor has launched a specialized air compressor solution tailored specifically for laser cutting applications. Our all-in-one laser cutting air compressor system integrates:

✅ 1. Fully Integrated System for Easy Installation

- No need for separate depósitos de aire, dryers, or filters

- Simplified piping and service setup

- One-stop support—no multiple vendors

✅ 2. High-Efficiency PM VSD Screw Air Compressor

- Permanent magnet variable speed drive ensures energy savings and stable pressure.

🔗 Discover our energy-efficient screw air compressors

✅ 3. Advanced Refrigerated Dryer + 4-Stage Filtration

- Removes moisture, oil, and particles for ultra-clean air.

✅ 4. Low Noise & Vibration

- Noise level < 70 dB(A), using vibration dampening and flexible piping design.

✅ 5. Smart Cooling Controls

- Seasonal fan control to prevent oil emulsification and maintain ideal oil temperature.

✅ 6. Centralized Condensate Drainage

- Keeps the production floor clean and dry.

Air Quality After Treatment

- Pressure Dew Point: 2–5°C

- Oil Content: ≤ 0.001 ppm

- Particle Size: 0.01 μm

🔗 View our full range of integrated air compressor systems

Real-World Application: Laser Cutting Industry Success

Baldor’s laser cutting dedicated compressor has been successfully adopted across metalworking, precision engineering, and manufacturing sectors, providing customers with a clean and stable air supply that directly enhances laser cutting quality and efficiency.

Get in Touch

Looking for a reliable and efficient air solution for your laser cutting system?

📞 Contact your nearest Baldor service center or visit our website for product details and expert advice.