PM-II & LPM-II Series Two-Stage Permanent Magnet Screw Air Compressor

Maximum Efficiency | Intelligent Control | Industry-Leading Energy Savings

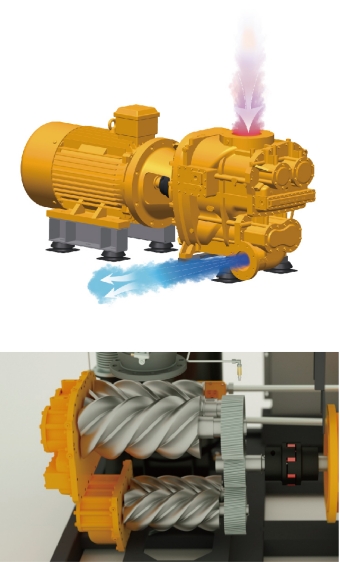

Optimized Two-Stage Compression for Maximum Efficiency

En Baldor PM-II & LPM-II Series are high-performance two-stage permanent magnet screw air compressors, engineered to provide exceptional energy savings, ultra-reliable operation, and long-lasting performance. Featuring IE4 Permanent Magnet Motors, Optimized Two-Stage Compression Technology, and an Intelligent IoT Control System, these compressors are the perfect solution for industrial applications requiring high-efficiency compressed air.

Why Choose the PM-II & LPM-II Series?

✅ Two-Stage Compression for 15% More Energy Savings – Reduces energy consumption compared to single-stage models.

✅ IE4 Permanent Magnet Motor – Up to 50% energy savings, with ultra-high efficiency.

✅ Variable Speed Drive (VSD) Technology – Dynamically adjusts airflow to match real-time demand.

✅ Optimized Cooling & Lubrication System – Extends component lifespan and ensures consistent performance.

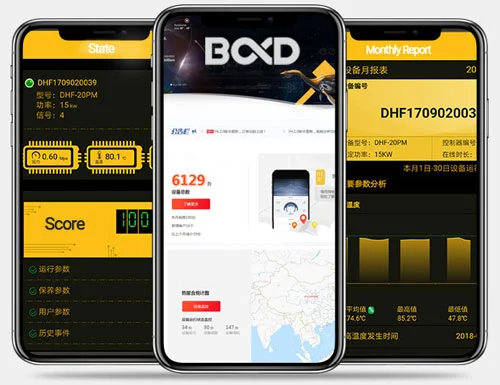

✅ Advanced Intelligent Control System – Remote monitoring, predictive maintenance, and real-time diagnostics.

Discover the Power of Two-Stage Compression

Explore how Baldor’s PM-II & LPM-II Series Two-Stage Permanent Magnet Screw Air Compressors are transforming industrial efficiency with advanced compression technology, smart automation, and superior energy performance.

✅ Enhanced Two-Stage Compression | Higher Efficiency & Lower Energy Costs

✅ Smart AI Control | Remote Monitoring & IoT-Based Performance Tracking

✅ High-Durability Airend | Longer Service Life & Lower Maintenance Costs

Join the Smart Manufacturing Revolution

Innovative Technology for Peak Performance

🔹 Two-Stage Compression System – Delivers higher pressure output while consuming less energy.

🔹 IE4 Permanent Magnet Motor – Reduces power consumption and enhances reliability.

🔹 Variable Speed Drive (VSD) System – Prevents energy waste by dynamically adjusting motor speed.

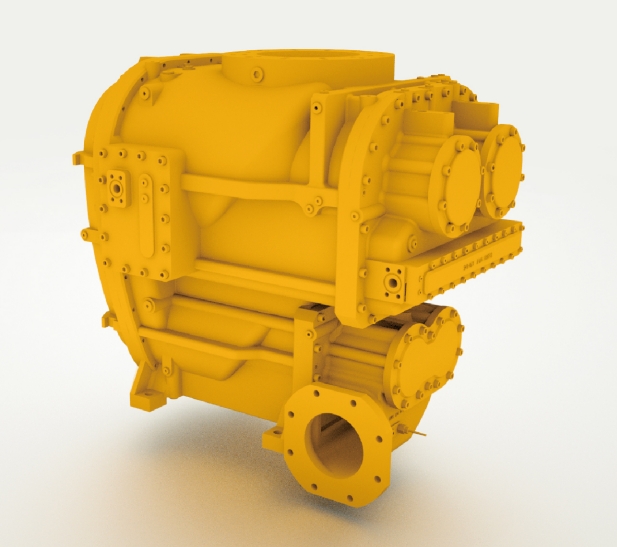

🔹 Advanced Airend Design – Precision-engineered rotors ensure optimal performance and minimal wear.

🔹 Enhanced Cooling System – Keeps operating temperatures stable, even in harsh industrial environments.

🔹 Smart Cloud-Based Control System – Features real-time monitoring, automated alerts, and performance analytics.

Premium Parts, Superior Performance

📌 High-Efficiency Airend – Features a two-stage rotor for improved compression efficiency.

📌 IE4 Permanent Magnet Motor – Achieves 98% efficiency with minimal energy loss.

📌 Smart Inverter & VSD Control – Adjusts compressor speed according to air demand.

📌 Oil Separation System – Delivers clean, high-purity compressed air.

📌 Heavy-Duty Cooling System – High-performance cooling fans prevent overheating.

📌 Intelligent Touchscreen Controller – Provides real-time performance analytics and automated system adjustments.

Digital & Intelligent Configuration Options

Smart Cloud-Based Monitoring for 24/7 Reliability

Intelligent Cloud Control System:

📡 Smart IoT Monitoring: Access live compressor data remotely.

📊 AI Predictive Maintenance: Automatic failure detection and alert system.

🔧 Modular Expansion Capabilities: Customize with additional air treatment options.

Smart Control System Benefits:

✅ Cloud-Based Remote Management

✅ Energy Optimization Reports

✅ Automatic Load Balancing for Peak Efficiency

Energy Savings & Cost Efficiency

💰 Cut Energy Consumption by 50% Compared to Standard Compressors

📈 Energy Savings Example: A factory replacing a 75 kW single-stage compressor with a PM-II 75 kW two-stage model can save over $18,000 annually in electricity costs.

- Traditional single-stage compressors generate higher energy losses, increasing electricity costs.

- PM-II & LPM-II Series Two-Stage Compression reduces compression workload, lowering thermal buildup and boosting efficiency.

- ROI within 1-2 years – Rapid payback period due to significant cost savings on electricity and maintenance.

Ready to Transform Your Operations?

Engineered for Maximum Efficiency & Reliability

PM-II Series (Standard Pressure Applications)

| Power Supply:380V/415V/440V/460V/3ph/50Hz/60Hz Cooling method: air cooling or water cooling Ambient temperature:-5-+40℃ | Exhaust temperature:=Ambient temperature+15℃ | |||||||||

| Operating voltage:0.7/0.6-0.8 | |||||||||

| Model | M3/min | Power | Size(mm) | Inch | KG | DB(A) | Liter | ||

| L | W | H | |||||||

| BD-75PM-II | 5.08-12.7 | 55 | 2200 | 1550 | 1800 | ZG2* | 1900 | 78±2 | 85 |

| BD-100PM-II | 6.6-16.5 | 75 | 2200 | 1550 | 1800 | ZG2″ | 1950 | 78±2 | 85 |

| BD-125PM-II | 8.08-20.2 | 90 | 3044 | 1844 | 50 | DN80 | 2800 | 80±2 | 100 |

| BD-150PM-II | 9.68-24.2 | 110 | 3044 | 1844 | 1850 | DN80 | 3000 | 80±2 | 100 |

| BD-175PM-II | 11.2-28.0 | 132 | 84 | 2034 | 2000 | DN100 | 4000 | 83±2 | 144 |

| BD-200PM-II | 13.44-33.6 | 160 | 3184 | 2034 | 2000 | DN100 | 4400 | 83±2 | 144 |

| BD-250PM-II | 15.12-37.80 | 185 | 3684 | 2306 | 2440 | DN125 | 5500 | 85±2 | 188 |

| BD-275PM-II | 16.4-41 | 200 | 3684 | 2306 | 2440 | DN125 | 5800 | 85±2 | 188 |

| BD-300PM-II | 18-45 | 220 | 3684 | 2306 | 2440 | DN125 | 6000 | 85±2 | 188 |

| BD-350PM-II | 21.08-52.7 | 250 | 3684 | 2306 | 2440 | DN125 | 6500 | 85±2 | 188 |

| BD-400PM-II | 22.4-56 | 280 | 3684 | 2306 | 2440 | DN125 | 8500 | 88±2 | 260 |

| BD-450PM-II | 25-62.5 | 315 | 3684 | 2306 | 2440 | DN125 | 9500 | 88±2 | 260 |

| BD-500PM-II | 28.88-72.2 | 355 | 4310 | 2300 | 2480 | dn150 | 10000 | 88±2 | 350 |

| BD-550PM-II | 32.8-82 | 400 | 4310 | 2300 | 2480 | DN200 | 11000 | 88±2 | 350 |

| BD-600PM-II | 37.24-93.1 | 450 | 4310 | 2300 | 2480 | DN200 | 11500 | 88±2 | 350 |

| BD-650PM-I | 40.2-100.5 | 500 | 4800 | 2300 | 2500 | DN250 | 15000 | 93±2 | 400 |

LPM-II Series (Low Pressure Applications)

| Power Supply:380V/415V/440V/460V/3ph/50Hz/60Hz Cooling method: air cooling or water cooling Ambient temperature:-5-+40℃ | Exhaust temperature:=Ambient temperature+15℃ | |||||||||

| Operating voltage:0.45/0.3-0.45 | |||||||||

| Model | M’/min | Power | SIZE(mm) | Inch | KG | DB(A) | Liter | ||

| L | W | H | |||||||

| BD-30LPM-II | 2.57-6.43 | 22 | 1600 | 1150 | 1370 | ZG11/2″ | 900 | 75±2 | 35 |

| BD-50LPM-II | 4.29-10.71 | 37 | 1800 | 1250 | 1550 | ZG2″ | 1500 | 78±2 | 75 |

| BD-75LPM-II | 6.6-16.5 | 55 | 2200 | 1550 | 1800 | DN80 | 2150 | 78±2 | 85 |

| BD-100LPM-II | 8.28-20.7 | 75 | 2200 | 1550 | 1800 | DN80 | 2200 | 78±2 | 85 |

| BD-125LPM-I | 10.24-25.6 | 90 | 3044 | 1844 | 1850 | DN80 | 3000 | 80±2 | 100 |

| BD-150LPM-II | 12-30 | 10 | 3184 | 2034 | 2000 | DN100 | 4000 | 80±2 | 144 |

| BD-175LPM-II | 15.2-38 | 132 | 3684 | 2306 | 2440 | DN125 | 5300 | 83±2 | 188 |

| BD-200LPM-II | 17.6-44 | 160 | 3684 | 2306 | 2440 | DN125 | 5500 | 83±2 | 188 |

| BD-250LPM-II | 20-50 | 185 | 3684 | 2306 | 2440 | DN125 | 5800 | 83±2 | 188 |

| BD-275LPM-II | 22-55 | 200 | 3684 | 2306 | 2440 | DN125 | 6000 | 83±2 | 260 |

| BD-300LPM-II | 24.4-61 | 220 | 3684 | 2306 | 2440 | DN125 | 6500 | 83±2 | 260 |

| BD-350LPM-II | 26-65 | 250 | 3684 | 2306 | 2440 | DN125 | 7000 | 83±2 | 260 |

| BD-400LPM-I | 30.76-76.9 | 280 | 4310 | 2300 | 2480 | DN150 | 10000 | 88±2 | 350 |

| BD-450LPM-II | 33-82.5 | 315 | 4310 | 2300 | 2480 | DN200 | 11000 | 88±2 | 350 |

| BD-500LPM-II | 40.52-101.3 | 355 | 4310 | 2300 | 2480 | DN200 | 11500 | 88±2 | 350 |

Certifications & Quality Assurance

🌍 Compliant with Global Energy and Safety Standards

✅ ISO 9001 Certified for Quality & Reliability

✅ CE Marked for Safety & Energy Compliance

✅ International Energy Efficiency Standards Approved

💡 Upgrade to the PM-II & LPM-II Series Today!

Contact us now to explore how the PM-II & LPM-II Series can maximize your air system efficiency and reduce costs.

Nos gustaría trabajar con usted

Discover how Baldor’s Digital Air Compressor Station can revolutionize your compressed air system. Contact our experts for a personalized consultation and quote tailored to your needs.