A well-known household chemical company in Sichuan Province, serving as a production base and logistics hub for the Libai Group in Southwest China, has successfully saved $76,000 annually by upgrading its compressed air system with Baldor’s Class-A energy-efficient smart compressed air station. This company, covering more than 300 acres, includes multiple plants for liquid detergent, soap production, and washing powder manufacturing, and is a leader in the household chemical industry in Southwest China.

Challenges Before the Energy Retrofit

Like many other enterprises, this chemical company faced several operational inefficiencies due to outdated air compressor management:

- Manual Air Compressor Management: The system relied on manual control to switch compressors on and off, leading to significant energy waste from delayed shutdowns.

- Excessive Energy Consumption: To ensure enough air supply, workers often started an extra compressor, leading to unnecessary energy use. Sudden demand spikes, however, left compressors unable to meet needs.

- Unexpected Compressor Failures: Breakdowns were only discovered when production was affected, requiring the manual activation of backup compressors, causing further delays.

- Uneven Equipment Usage: Some compressors ran far longer than others, leading to increased wear, higher failure rates, and improper equipment rotation that affected longevity.

Baldor’s Smart Compressed Air Solution

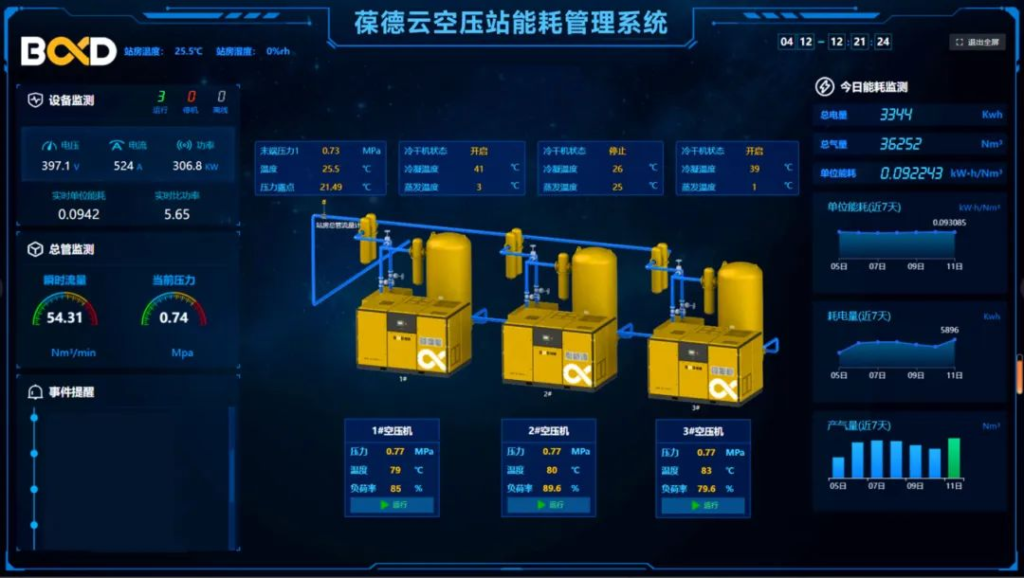

Baldor’s Class-A energy-efficient smart compressed air station, powered by IoT and AI technology, is an integrated hardware and software solution—the first of its kind in the industry. The system collects real-time data from the air station, analyzes and optimizes critical data, including energy consumption and air-to-electricity ratios, and dynamically adjusts compressor loads based on actual demand, thereby reducing electricity usage and extending equipment life.

Here’s how Baldor helped the company reduce its energy consumption:

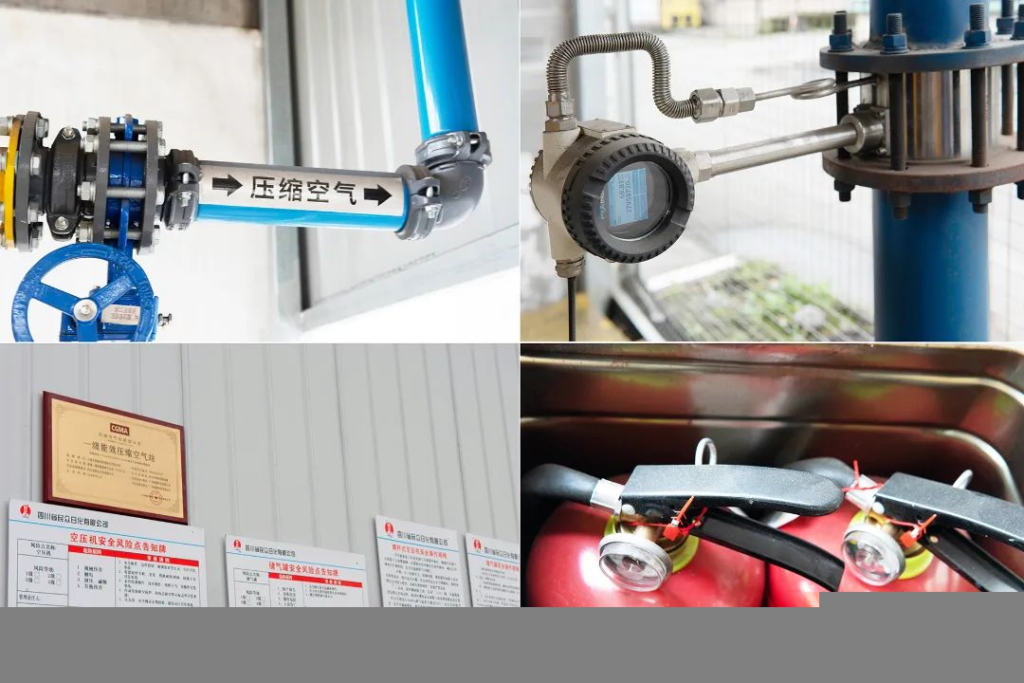

- Optimized System Design: Analyzed air source, pipelines, and equipment status to identify leaks and inefficiencies, implementing necessary optimizations.

- Energy-Saving Equipment: Replaced outdated, energy-intensive compressors with Class-A energy-efficient permanent magnet variable frequency two-stage compressors. Large-capacity air storage tanks were installed to absorb fluctuations in air demand, reducing overall energy consumption.

- Smart Control System: Installed an intelligent compressor control system that effectively matches air output and pressure demand, optimizing energy consumed during each cycle.

- Energy-Efficient Dryers: Old, inefficient dryers were replaced with energy-saving versions, integrated into the smart control system.

- Real-Time Energy Monitoring: Installed flow meters, electricity meters, and pressure sensors to monitor energy consumption in real time, providing continuous feedback to operators.

- Optimized Pressure Settings: The air supply pressure, previously set between 0.75-0.78 MPa, was adjusted to a more efficient 0.72 MPa without affecting production, ensuring stable pressure while reducing energy consumption.

Results of the Energy Retrofit

After the retrofit was completed in June 2023, the results were remarkable, with continuous monitoring of the system providing the following improvements:

- Smart Integrated Control: The system automatically manages compressor operation based on real-time demand, including automatic switching to backup compressors in case of failure, minimizing energy use while maintaining production efficiency.

- Class-A Energy Efficiency: The energy-efficient compressors now operate in balance, with equipment rotation ensuring equal operating hours, reducing wear and maintaining optimal efficiency across the system.

- Stable Pressure: The system not only reduced energy use but also ensured a constant air pressure, critical for maintaining product quality and reducing waste.

- Lean Energy Management: Real-time, automatic cost allocation for energy consumption makes it easier to track and control energy costs, supporting lean management goals and further reducing energy waste.

Key Performance Indicators:

- Pre-Retrofit Energy Consumption: 0.146 kWh/Nm³

- Post-Retrofit Energy Consumption: 0.095 kWh/Nm³

- Energy Savings: A 35% reduction in energy consumption, translating into annual savings of approximately $76,000.

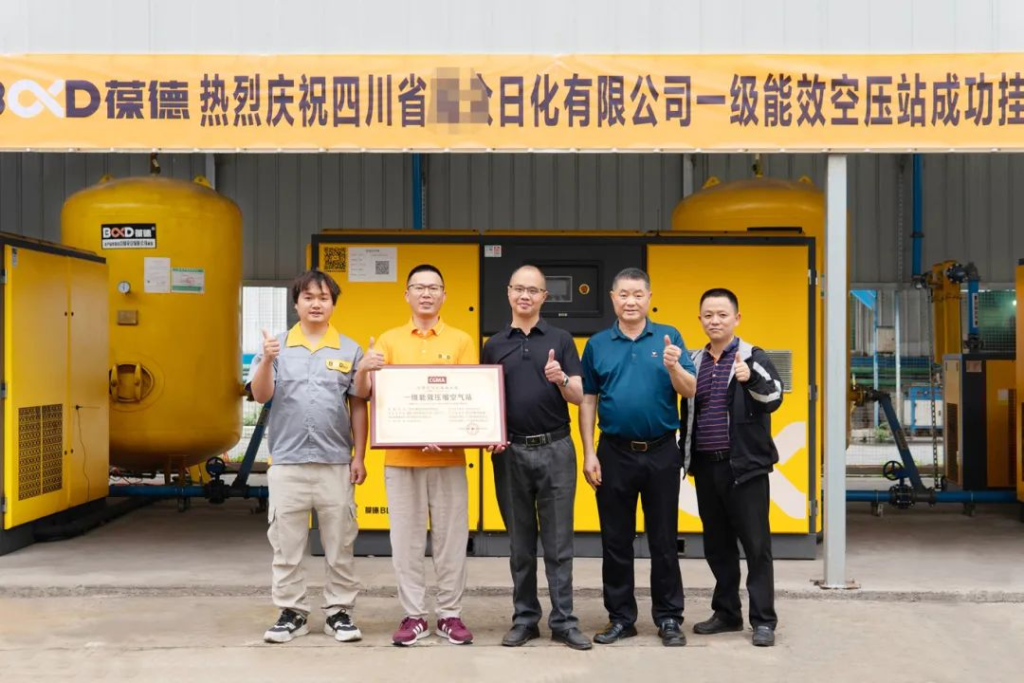

Client Satisfaction and Certification

The energy savings and efficiency improvements were verified through extensive data collection and analysis. The compressed air station received certification for its Class-A energy efficiency from national quality supervision agencies, and the company is now benefiting from substantial cost reductions.

Key Benefits of Baldor’s Smart Compressed Air System

- AI-Driven Automation: The system automatically adjusts compressor operation based on real-time air demand, ensuring efficient energy use.

- Energy Savings: The retrofit resulted in significant energy savings by using energy-efficient equipment and optimizing system operation.

- System Stability: Consistent air supply pressure ensures stable production while reducing waste.

- Real-Time Monitoring and Control: Energy monitoring and control systems enable businesses to track and manage energy consumption in real time, minimizing unnecessary costs.

- Improved Equipment Lifespan: Smart rotation and load management extend compressor life and reduce the likelihood of breakdowns.

Why Choose Baldor for Your Energy Efficiency Needs?

Baldor’s Class-A energy-efficient smart compressed air systems have been proven to deliver outstanding results in reducing energy consumption and costs. With advanced IoT-based solutions, you can ensure your air compressor system operates at its highest efficiency, lowering both operational costs and environmental impact.

Explore Baldor’s smart compressed air solutions and discover how we can optimize your system for greater energy savings and efficiency.