Chapter 1

Chapter 2

Chapter 3

Chapter 4

Chapter 5

Chapter 6

Food and Beverage: Ensuring clean, hygienic packaging and processing.

| Type | Best For | Key Advantage | Downside |

| Piston (Reciprocating) | Small-scale tools | Affordable, simple | Not for 24/7 use |

| Rotary Screw | Factories, construction | Quiet, reliable | Expensive upfront |

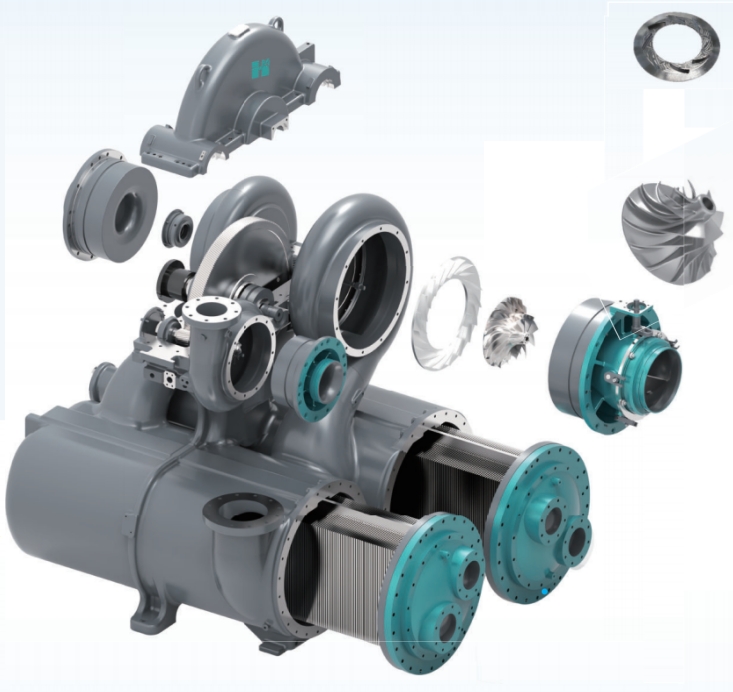

| Centrifugal | Large industrial operations | Handles massive airflow | Complex and pricey |

| Oil-Injected | Tough industries | Durable and efficient | Needs oil maintenance |

| Oil-Free | Clean air applications | 100% clean air, hygienic | Higher cost, faster wear |

Picking a compressor that’s too small for your needs can lead to performance issues and downtime.

A cheaper compressor might cost more in energy and repairs over time. Always consider total cost of ownership (TCO).

Poorly maintained compressors lose efficiency and are more likely to break down, increasing long-term costs.

Compressors with slightly higher upfront costs but better energy efficiency often pay for themselves in savings.

Select a compressor based on your specific needs to optimize efficiency and reduce unnecessary costs.

Regular upkeep ensures long-term reliability, fewer breakdowns, and lower overall expenses.

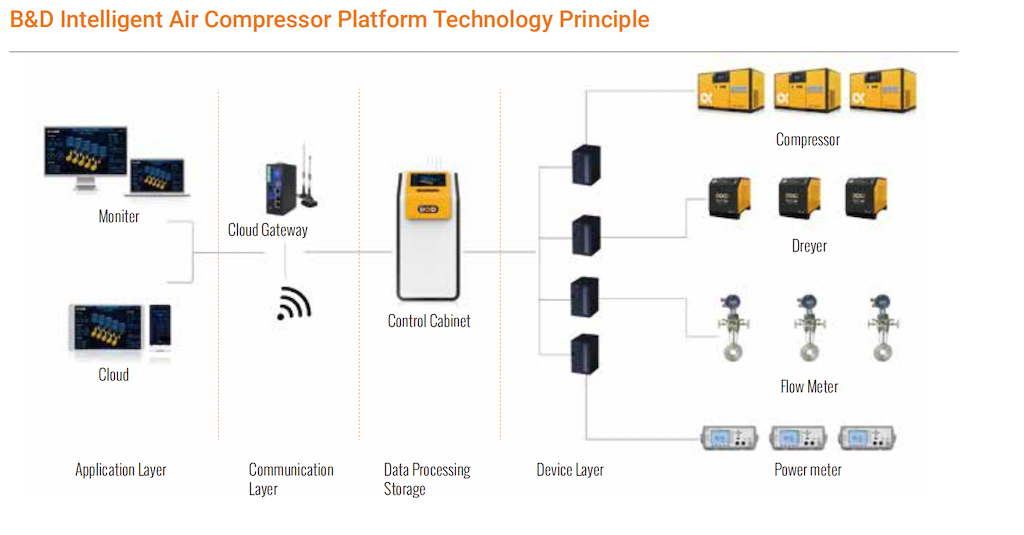

Tools like IoT and AI can streamline monitoring, improve efficiency, and simplify compliance.

Energy-efficient models and green practices save money while supporting environmental goals.

Envoyez-nous un message si vous avez des questions ou demandez un devis. Nos experts vous répondront dans les 24 heures et vous aideront à sélectionner la valve qui vous convient.

Envoyez-nous un message si vous avez des questions ou demandez un devis. Nos experts vous répondront dans les 24 heures et vous aideront à sélectionner la valve qui vous convient.