Introduction :

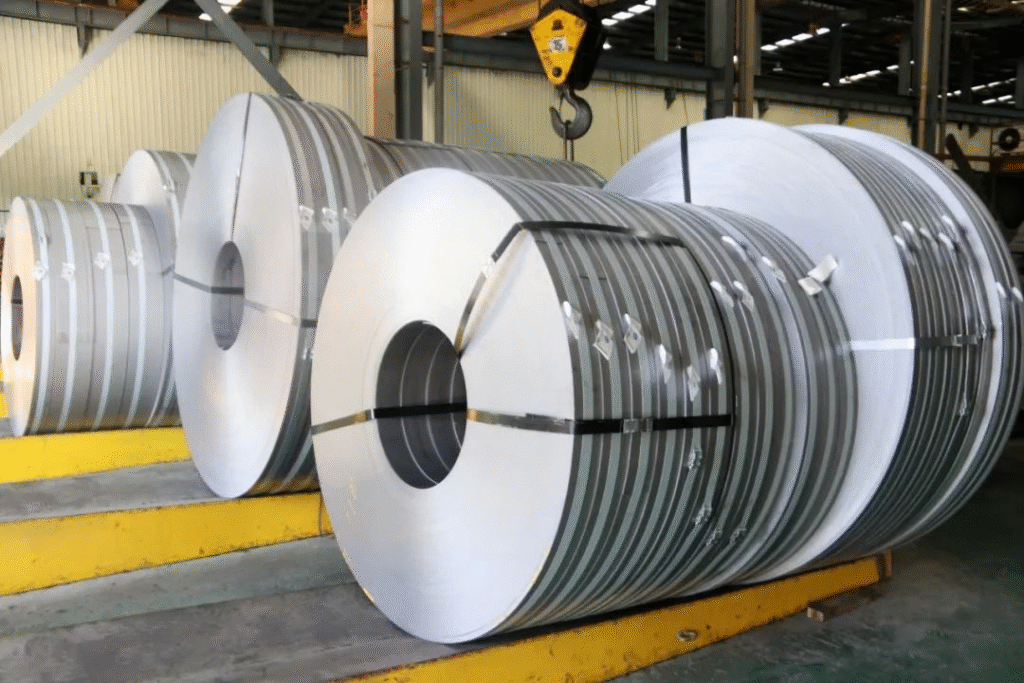

Guangzhou Meiya Co., Ltd., established in November 1995, covers an area of 83 acres and is listed on the Hong Kong Stock Exchange. Specializing in the research and production of stainless steel pipes, steel cutting, carbon steel precision tubeset automotive steel pipe plates, Meiya is recognized as a high-tech enterprise by the Chinese government.

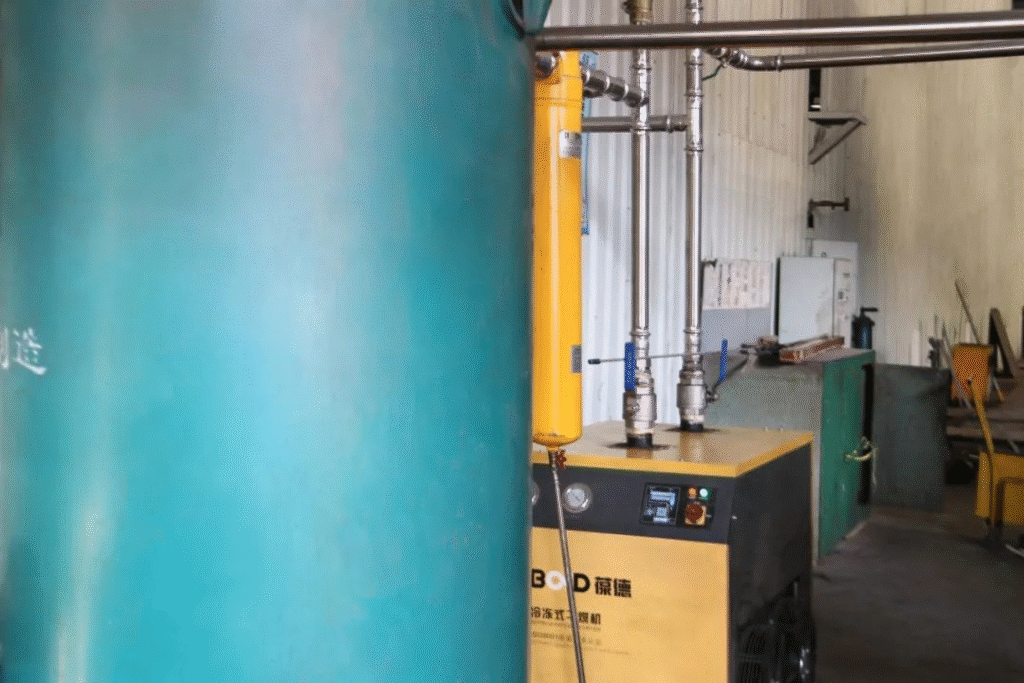

In industries like metal production, air compressors play a crucial role in powering everything from lubrication systems to pneumatic tools, such as wind hammers, grinders, and lifting systems. Since air compressors account for up to 30% of the total electricity usage in metal manufacturing, choosing energy-efficient, environmentally friendlyet quiet compressors is essential for optimizing operations.

Air Compressor Applications in the Metal Industry:

In the metal industry, air compressors are primarily used for:

- Loading and conveying systems

- Lubrication systems

- Pneumatic tools (wind hammers, grinders, hoists, lifting devices)

- Oxygen cutting, welding, pipe manufacturing, and other power-driven applications

- Instrument air supply and purging systems

Selecting the right air compressor can significantly impact la consommation d'énergie, operational stabilityet overall product quality. High-quality compressors ensure stable air pressure, preventing defects such as slag adhesion in stainless steel pipes and plates, which helps maintain high production standards.

Meiya’s Partnership with Baldor:

In 2019, Meiya Co., Ltd. partnered with Baldor and selected the BD-150LPM-II Intelligent Permanent Magnet Variable Frequency Air Compressor. Since then, the company has benefited from:

- More stable airflow

- Significant energy savings

- Enhanced competitiveness in the industry

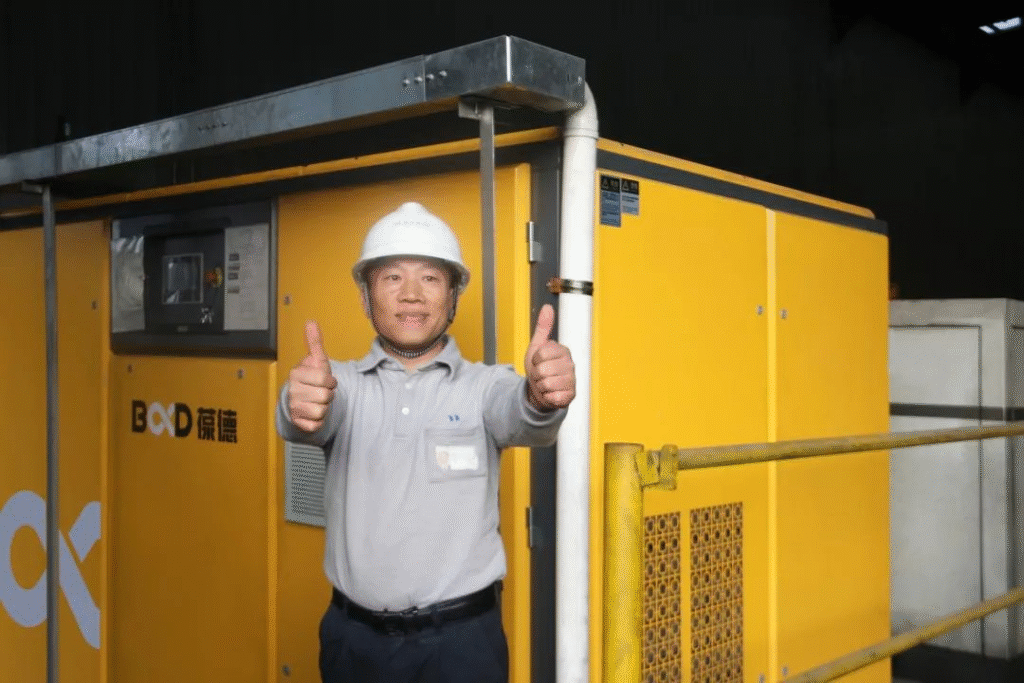

Interview with Meiya’s Assistant General Manager, Mr. Mo Shaowen:

Baldor: What is the most important factor for you when purchasing an air compressor?

Mr. Mo Shaowen (Meiya’s Assistant General Manager): Le stability of the equipment and its l'efficacité énergétique are our top priorities.

Baldor: As a prominent listed company, what aspects of Baldor’s air compressors attracted you during the selection process?

Mr. Mo Shaowen: First, we were impressed by Baldor’s meticulous factory management. Manufacturers with precise management demonstrate unique strengths. Second, the nature of our products requires high-performance air compressors and appropriate post-treatment equipment to meet our environmental standards. Third, Baldor’s intelligent permanent magnet variable frequency technology is truly industry-leading. After thorough selection, we were drawn to Baldor due to its numerous energy-saving case studies et cost-effective product combinations.

Baldor: After using Baldor air compressors for some time, what have been the highlights?

Mr. Mo Shaowen: Since starting with Baldor compressors in July 2019, we’ve noticed several improvements:

- Compared to our previous compressors, Baldor compressors are quieter and meet the environmental standards required in Guangzhou, a city that values sustainability.

- Energy savings have been remarkable. Previously, our air compressors consumed about 3,000 kWh of electricity per day. With Baldor’s compressors, we now use less than 2,000 kWh per day for the same output. This results in a savings of over 40,000 kWh per month, translating into an annual savings of approximately 200,000 RMB.

For a listed company like ours, these numbers speak for themselves, and we greatly appreciate the energy-saving benefits Baldor has provided.

Baldor’s Continued Commitment to Energy Efficiency:

Meiya’s experience demonstrates the significant économies d'énergie et operational benefits that come with choosing the right air compressor. By selecting Baldor’s intelligent, energy-efficient solutions, Meiya has optimized its operations, reduced costs, and adhered to environmental standards.

En savoir plus sur les solutions d'économie d'énergie de Baldor :

To discover how Baldor can help your business improve l'efficacité énergétique and boost productivity, visiter Baldor Air Solutions.