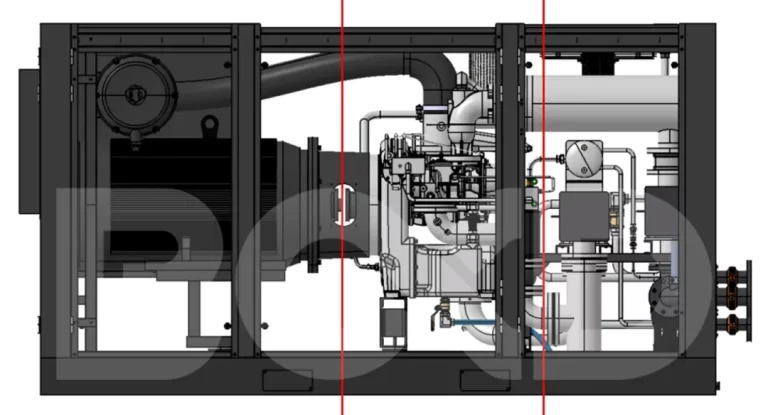

Che cos'è un compressore d'aria senza olio?

Un compressore d'aria oil-free è un tipo di compressore progettato per fornire aria compressa 100% oil-free. A differenza dei compressori a iniezione di olio, i compressori oil-free utilizzano tecnologie avanzate di tenuta e raffreddamento per eliminare la necessità di olio lubrificante nella camera di compressione. Questo garantisce che l'aria in uscita rimanga completamente incontaminata, rendendoli ideali per i settori con requisiti di purezza dell'aria molto severi, come quello farmaceutico, elettronico e della produzione alimentare.