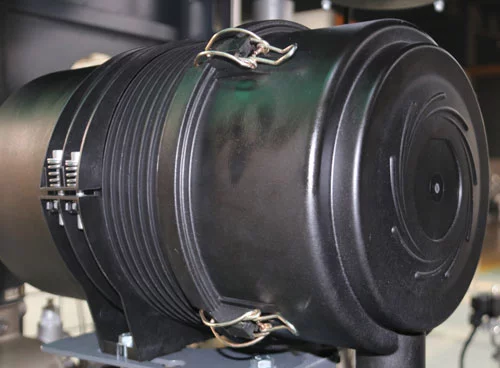

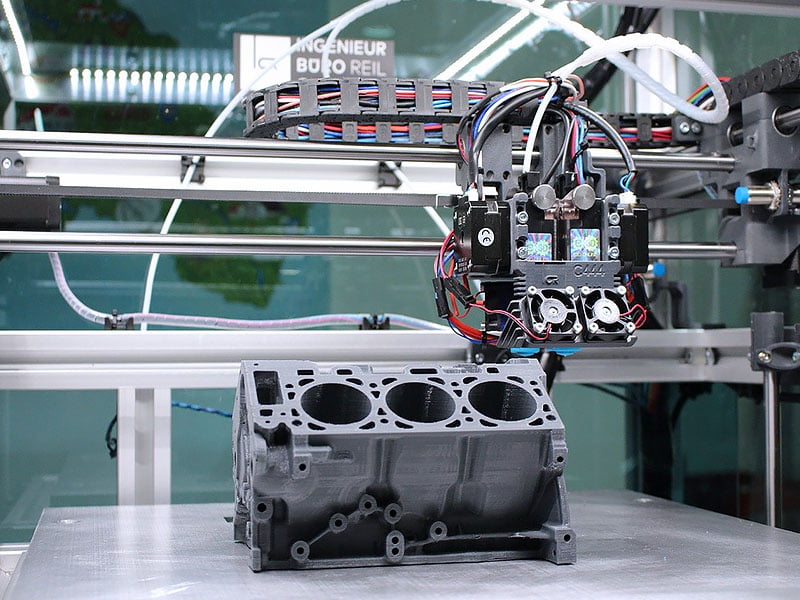

What is an Oil-Injected Air Compressor?

An oil-injected air compressor is a type of air compression system where oil is introduced into the compression chamber to serve as a coolant, lubricant, and sealing agent. This ensures smooth operation, reduces heat during compression, and minimizes wear on components. After compression, the air is filtered to remove oil particles, delivering clean, high-quality compressed air suitable for various industrial applications.