Introduction to Ha Long Foam

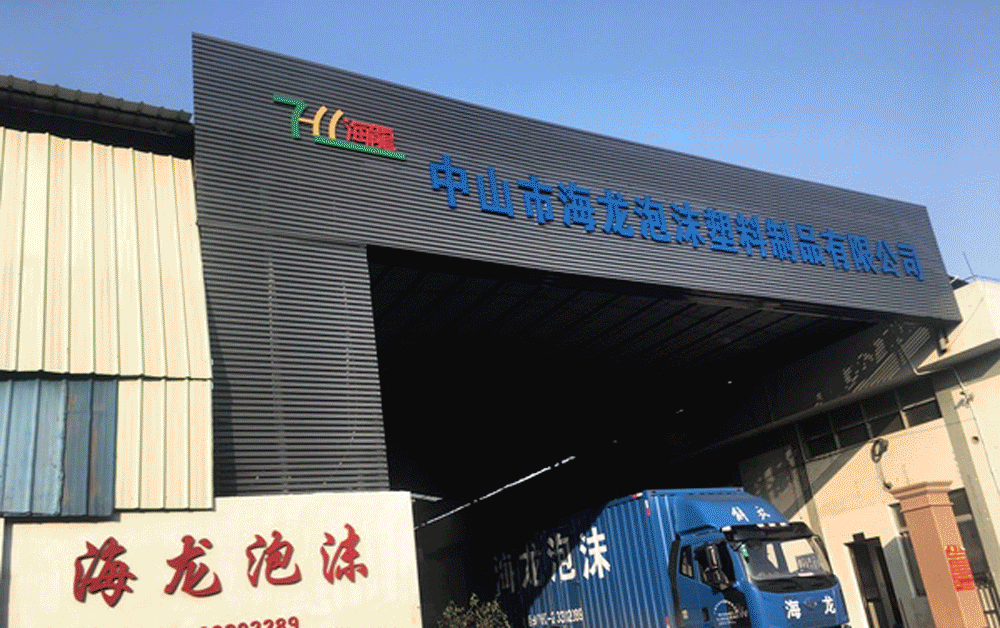

Located in Nantou Town, Zhongshan City, Guangdong Province, Ha Long Foam Plastic Products Co., Ltd. is a professional manufacturer of expandable polystyrene (EPS) foam products, primarily used in the electronics and home appliance industries. With a reputation for pragmatism, growthそして win-win development, Ha Long Foam has established itself as a leader in the foam industry.

Energy Efficiency: A Key Factor in the Foam Industry

In foam production, エネルギー消費 is a significant concern, especially when using compressed air systems. Air compressors are crucial throughout the entire manufacturing cycle, from:

- Raw material compression

- Pre-expansion

- Curing

- Molding

- Cleaning

- Cooling

Air compressor systems account for up to 70% of the total energy used in foam production. Therefore, selecting an 省エネ, environmentally friendlyそして quiet air compressor is critical for optimizing overall energy usage.

Baldor and Ha Long Foam: A Partnership for Sustainability

In 2019, Ha Long Foam partnered with バルドル to introduce the BD-150LPM Low-Pressure Intelligent Permanent Magnet Variable Frequency Air Compressor into their production line. Since implementing Baldor’s advanced technology, the company has seen noticeable improvements in エネルギー効率 and more stable compressed air production, giving them a competitive edge in the industry.

Energy Savings Achieved with Baldor Compressors

After tracking energy consumption for one year, Ha Long Foam recorded significant energy savings. Prior to Baldor’s system:

- Energy consumption for 10 tons of foam produced was 900 kWh per ton with their previous equipment.

After switching to Baldor’s intelligent air compressor, energy consumption dropped to 620 kWh per ton, representing a 34% reduction in energy usage. This substantial energy saving not only helped Ha Long Foam reduce operational costs but also contributed to their ongoing サステナビリティへの取り組み.

Customer Feedback: Ha Long Foam’s Experience with Baldor

In an interview, Mr. Yang, General Manager of Ha Long Foam, shared his thoughts on Baldor’s air compressors:

“Baldor’s air compressors have greatly improved our energy efficiency, providing a stable air supply and reducing our electricity costs. The Baldor Cloud maintenance reminders, accessible via mobile app, are a key benefit. Energy-saving is crucial in our sector, and Baldor has helped us achieve noticeable savings, enhancing our competitiveness in a challenging market.”

He further stated:

“We are confident in Ha Long Foam’s product quality and customer service. As we expand our production capacity, we will continue to choose Baldor’s high-quality エアコンプレッサー and share the benefits of energy savings with more users.”

Baldor: A Reliable Partner for the Future

Baldor remains committed to providing high-efficiency, stableそして cost-effective air compressor solutions. With continuous innovation and a focus on energy-saving technologies, Baldor ensures the safety そして success of its clients’ operations.

結論

At Baldor, customer satisfaction is our top priority. By delivering high-performance products, offering exceptional value, and providing outstanding service, we help clients exceed their expectations. For more information on how Baldor can assist your business with 省エネソリューション訪問 バルドル公式サイト.