Baldor Industrial Reciprocating Compressors

Powering Heavy Industries

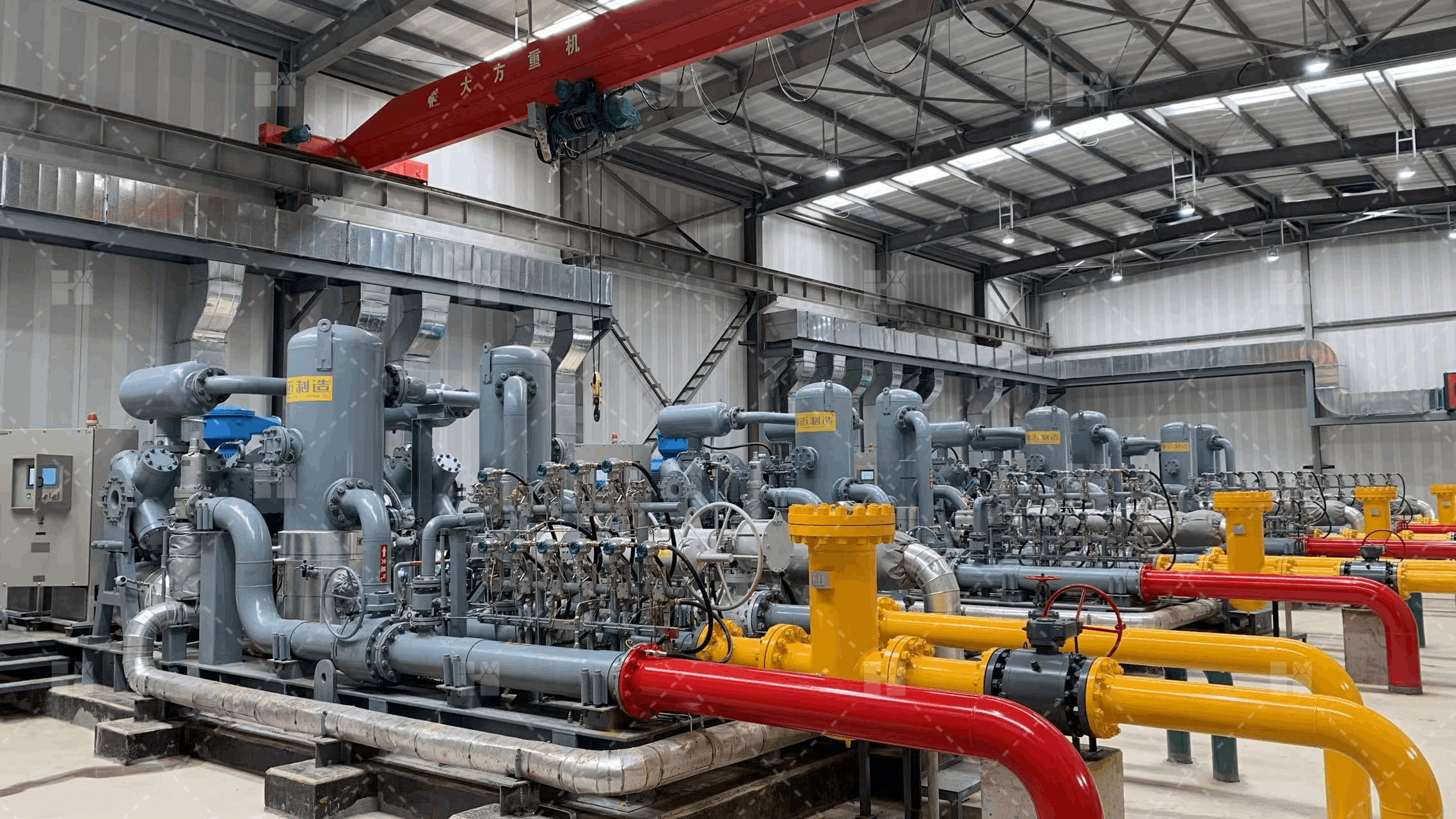

Why Choose Baldor’s Large-Scale Reciprocating Compressors?

Key Technologies & Benefits Section

- High Pressure Output: Delivers air pressure up to 350 bar, suitable for the most demanding industrial tasks.

- Large Capacity: Capable of handling airflows exceeding 50 m³/min, ensuring uninterrupted operations for large-scale facilities.

- Durable Construction: Heavy-duty frames and wear-resistant components designed for extreme conditions.

- Energy Efficiency: Optimized compression stages reduce energy consumption by up to 20%.

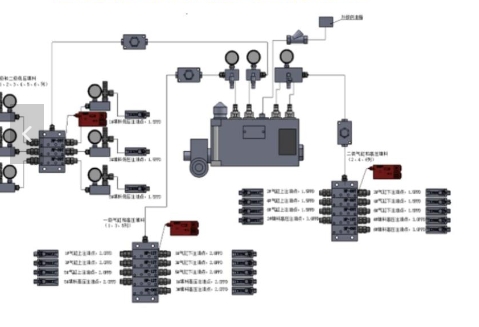

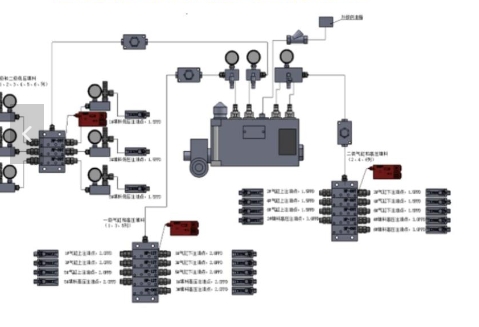

- Smart Monitoring System: Integrated with IoT-based controls for real-time performance monitoring and predictive maintenance.

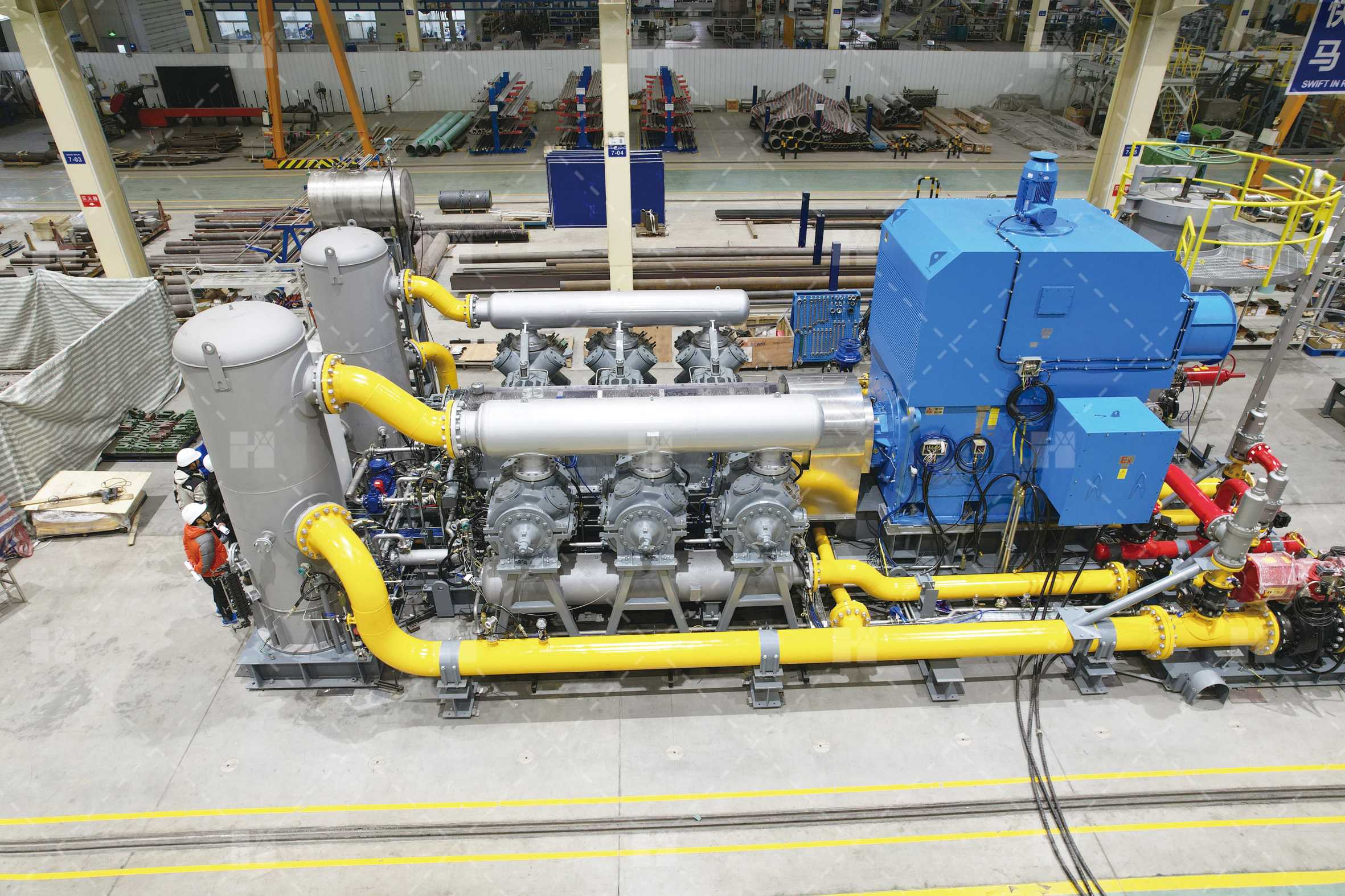

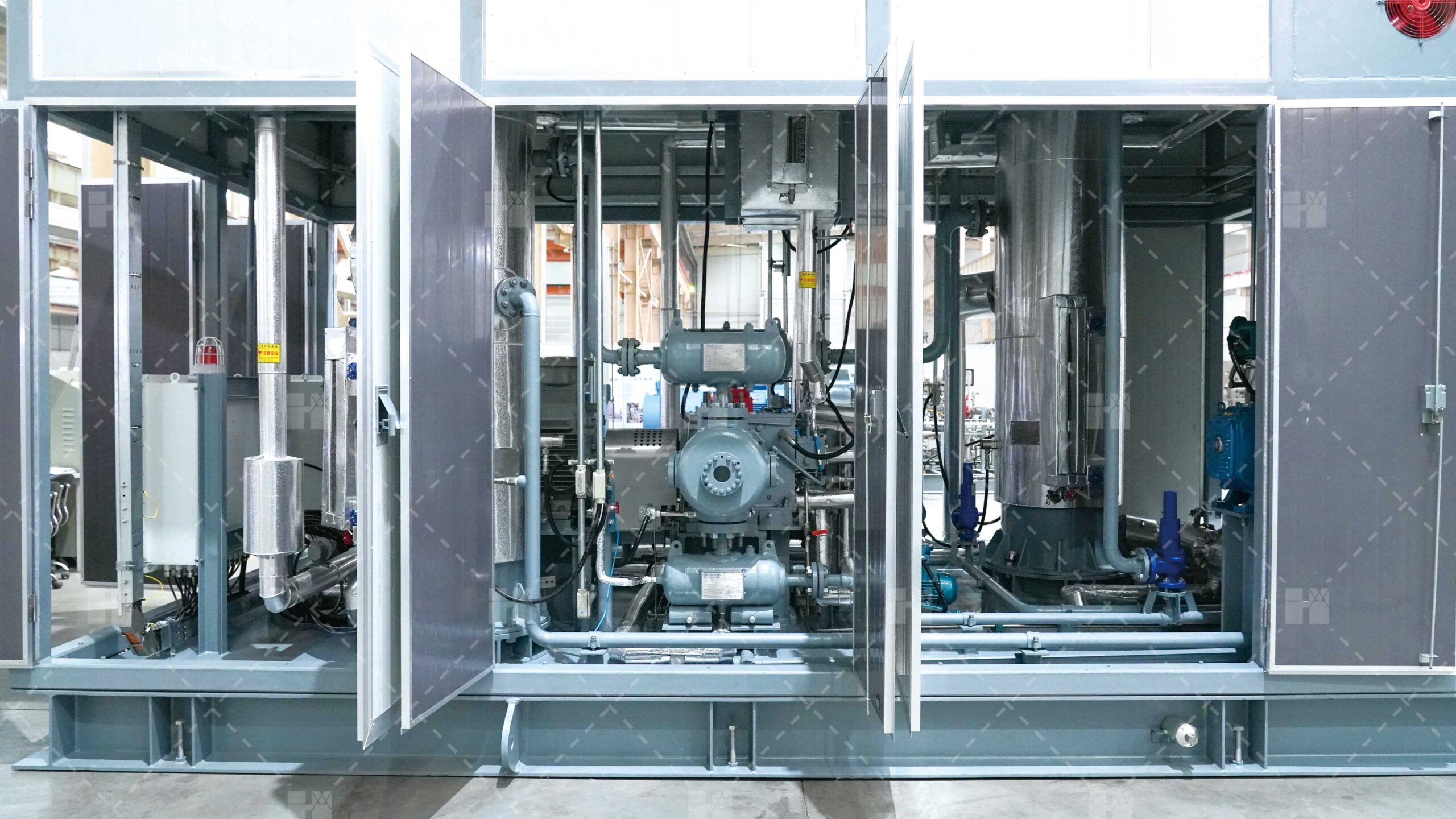

Full Industry Chain Manufacturing Capability

Assembly Capability

Casting Capability

One of the biggest casting suppliers in China and owns leading casting technology in the world. Annual output: 250,000 tons for iron casting and steel casting Maximum casting weight:100tons/piece.

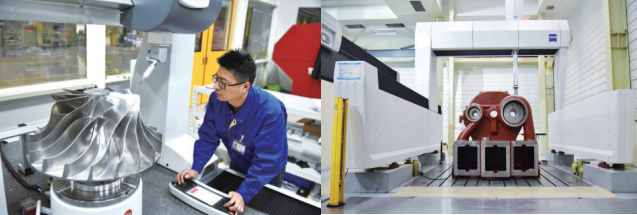

Machining Capability

Owns thousand sets of large, medium and small precision machining equipment, including global brands such as PAMA, TOS, SCHIESS, SKODA, OKUMA, etc. and meanwhile develops special equipment catering to machining requirements.

Welding Capability

Welding shop covers an indoor area of 110,000 square meters and has 300+ certified welders and full range of equipment for cutting, grooving, bending, welding, heat treatment, flaw detection, abrasive blasting and coating. The team has plenty performance and experience in the welding of such materials as carbon steel, stainless steel, duplex stainless steel, titanium alloy, chromium alloy, copper-nickel alloy, tantalum, et

Quality Assurance

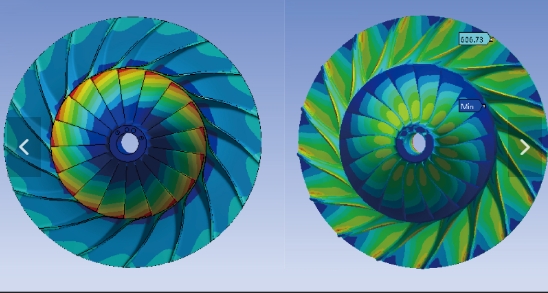

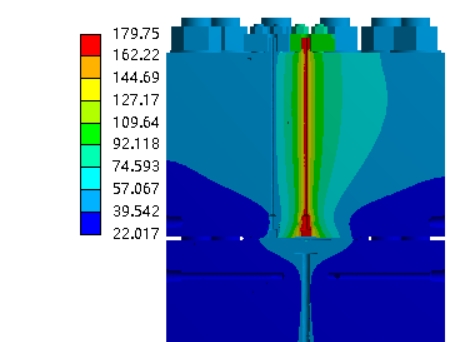

Baldor owns numerous advanced inspection and testing equipment and practices the concept of Design Development-Test Verification-Operation Optimization-Marketing-Continuous Innovation, which has achieved the all-round verification and testing of the critical design results on aerodynamic performance, structural strength and equipment heat exchange,etc., providing a strong guarantee on compressor efficiency, stability and reliability.

The test platform is equiped with 20000KVA power supply, every compressor receive 100% performance test to meet customer's needs.

Physical and Chemica

Parts Inspection

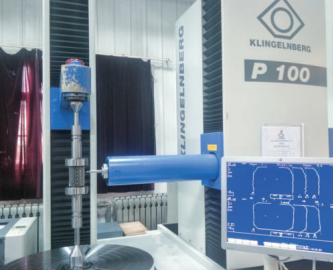

Gear Shaft Inspection

Rotor Dynamic Balance Test

Join the Smart Manufacturing Revolution

Technical Specifications Section

| Model | Crankshaft turns | Stroke/mm | Power/kW | Speed/RPM | Piston rod diameter/mm | Maximum gas rod load/kN |

| CHA | 2/4 | 76 | 216/432 | 600-1800/750-1800 | 28.5 | 58 |

| CHB | 2/4 | 90 | 300/600 | 900-1800 | 35 | 66 |

| CHD | 2/4 | 90 | 450/900 | 900-1800 | 40 | 90 |

| CHE | 2/4 | 127 | 886/1771 | 600-1400 | 51 | 178 |

| CHF | 2/4 | 152.5 | 1350/2700 | 600-1200 | 57.2 | 231 |

| CHG | 2/4/6 | 152.5 | 1350/2700/4050 | 600-1200 | 63.5 | 289 |

| CHJ | 2/4/6 | 178 | 1860/3720/5580 | 450-1000 | 70 | 334 |

| CHK | 2/4/6 | 152.5 | 2250/4500/6750 | 450-1200 | 70 | 334 |

Working Mechanism Section

Applications Section

Applications Section

あなたと一緒に働きたい

- +86 18621914675

- overseas@baldor-air.com