Mengpai Ceramics, a renowned brand in China’s sanitary ware manufacturing industry, successfully integrated Baldor’s intelligent compressed air station, achieving a 33.4% improvement in energy efficiency. The company operates three factories and one branch, producing high-quality ceramic products that set industry standards in design, glaze, and physical and chemical properties.

Baldor’s Smart Air Compressors Drive Energy Efficiency

In 2024, Mengpai Ceramics partnered with Baldor to enhance their production processes. The solution included 고효율 공기 압축기, advanced post-treatment equipment, a complete station design및 digital management system that provided reliable compressed air for their ceramic and sanitary ware production lines.

Challenges Before the System Upgrade

Before integrating Baldor’s smart compressed air station, Mengpai Ceramics faced several operational challenges:

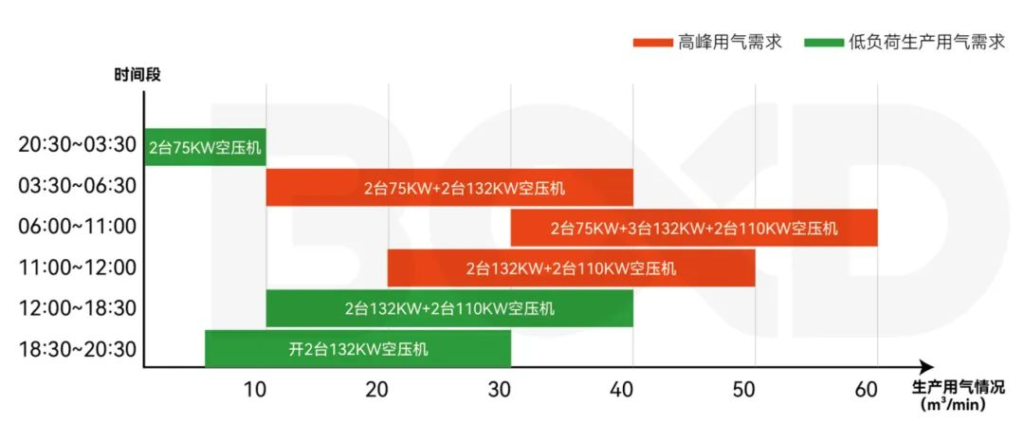

- Manual Management: The company’s production schedule included multiple time slots with varying air consumption, requiring manual control of air compressors. For example, during downtime at 6:30 PM, the compressors were often left running until 7:00 PM, wasting approximately 130 kWh of energy each time. Operators also frequently forgot to switch off the associated air dryers.

- Inefficient Operation: Compressor operation was based on manual judgments, leading to insufficient air supply 또는 unexpected shutdowns.

- Uneven Equipment Usage: Some equipment was overworked while others were underutilized, causing operational imbalances 그리고 increased failure rates.

- Manual Metering: The air station relied on manual readings, resulting in inaccuracies during cost calculations and difficulty in data analysis.

AI-Based Energy Efficiency Solution by Baldor

After conducting an energy audit and analysis, Baldor introduced several key upgrades to Mengpai Ceramics’ operations:

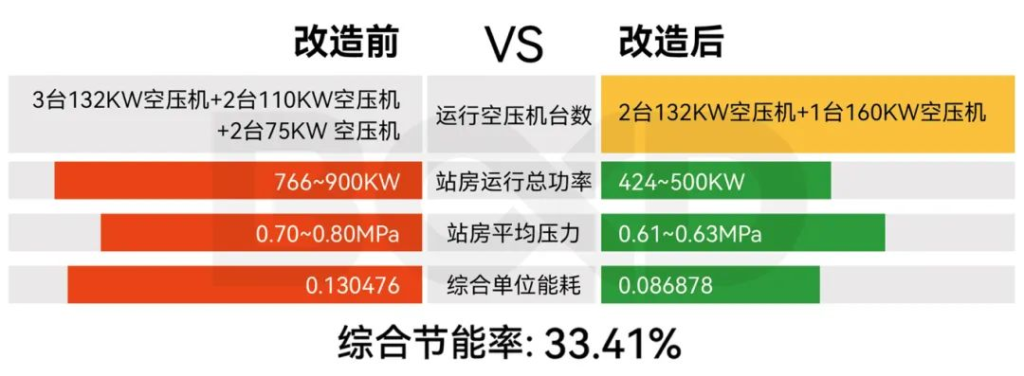

- System Design Optimization: The compressed air system’s pipeline, leakage, and equipment usage were optimized to ensure efficient operation.

- Energy-saving Upgrades: Baldor replaced old equipment with energy-efficient, two-stage variable frequency air compressors, advanced dryers, and other components to maximize energy savings.

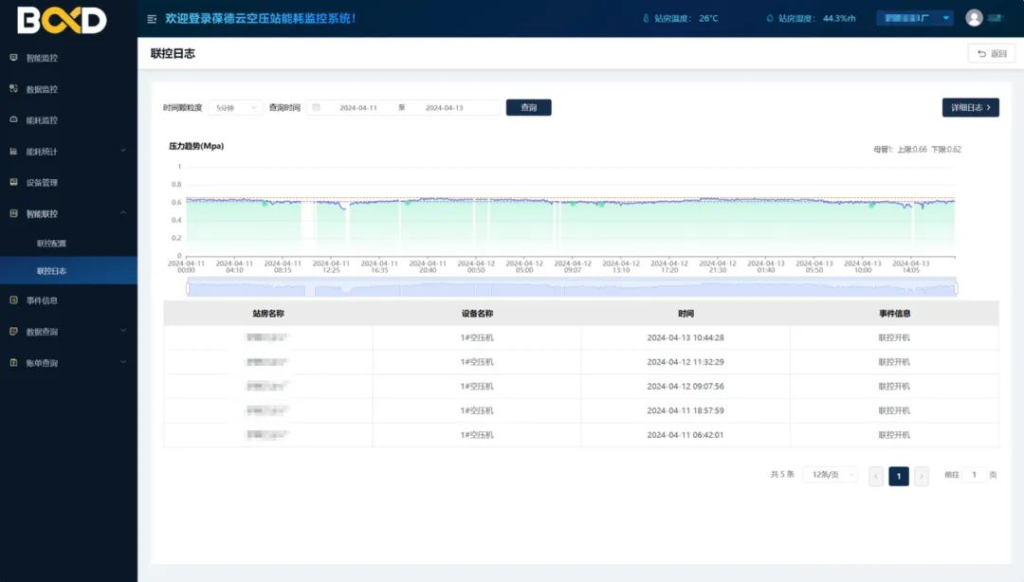

- Smart Management: A digital management system was installed to enable intelligent control of air compressors and dryers, ensuring optimal air pressure and minimal power consumption. Real-time monitoring was enabled using flow meters, electricity meters, and pressure sensors.

- Lean Improvements: After the upgrades, the system produced only the required amount of compressed air, maintaining a stable pressure of 0.63 MPa, reducing energy waste.

Baldor’s Intelligent Compressed Air Station

Baldor’s smart compressed air station, powered by IoT 그리고 AI, is the first of its kind to be recognized as a digital intelligent demonstration factory by the local government. The system provides an integrated hardware and software solution for managing compressed air stations efficiently. Key benefits include:

- Demand-based Operation: The system automatically adjusts air compressor operation according to demand, ensuring only the necessary amount of air is produced and optimizing energy consumption.

- Smart Rotation: Equipment is rotated automatically to ensure balanced usage, extending machinery lifespan.

- Constant Pressure: The system maintains consistent station pressure, reducing energy waste and lowering electricity costs.

- Intelligent Control: Compressors and post-treatment devices are automatically synchronized to ensure a stable supply of high-quality air.

- Energy Cost Allocation: The system provides automatic reporting and energy consumption distribution, facilitating lean management and cost optimization.

Impressive Energy Savings: A Case Study

The energy efficiency results after the upgrade are significant:

- Before the Upgrade: 에너지 소비량은 0.130476 kWh/Nm³.

- After the Upgrade: 에너지 소비가 다음과 같이 감소했습니다. 0.086878 kWh/Nm³, reflecting a 33.4% reduction in energy use.

Real-time monitoring and AI-driven control continue to ensure that Mengpai Ceramics operates at top efficiency while keeping energy costs low.

Key Features of Baldor’s Intelligent Compressed Air System

- Automatic Start/Stop: Compressors are turned on and off based on demand, preventing unnecessary energy waste.

- Smart Load Balancing: Equipment usage is balanced, preventing overuse and extending machinery life.

- Stable Pressure: The system maintains constant pressure, reducing energy waste.

- Intelligent Integration: Compressors and dryers are automatically controlled for seamless operation.

- Energy Monitoring: Real-time energy usage data and automatic reporting for optimized energy management.

Conclusion: Optimizing Energy Use and Driving Efficiency

Baldor’s intelligent air compressor solutions are revolutionizing energy efficiency across industries. Mengpai Ceramics’ success story demonstrates the significant benefits of adopting smart, AI-powered systems for compressed air management. With an average energy savings rate of over 35% across various case studies, Baldor is helping companies reduce costs, increase productivity, and embrace digital transformation in energy management.

Discover Baldor’s Energy-Saving Solutions

To learn more about how Baldor’s solutions can help your company save energy and improve efficiency, visit our website.