Что такое безмасляный воздушный компрессор?

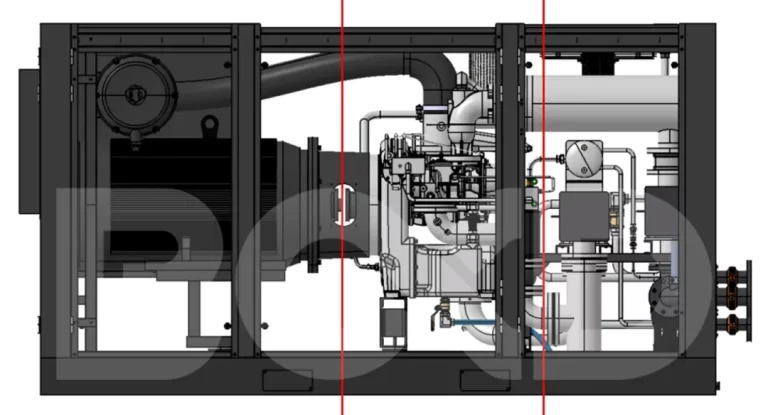

Безмасляный воздушный компрессор - это тип компрессора, предназначенный для подачи безмасляного сжатого воздуха 100%. В отличие от маслозаполненных компрессоров, в безмасляных компрессорах используются передовые технологии уплотнения и охлаждения, позволяющие отказаться от смазочного масла в камере сжатия. Благодаря этому воздух на выходе остается полностью незагрязненным, что делает их идеальными для отраслей со строгими требованиями к чистоте воздуха, таких как фармацевтика, электроника и пищевое производство.