Excessive oil consumption in screw air compressors is a common and concerning issue. Not only can it contaminate downstream equipment like air dryers ve precision filters, but it also affects product quality and can damage production equipment. Understanding the root causes of high oil consumption is essential for effective maintenance and operation.

1. Main Cause: Oil Separator Malfunction

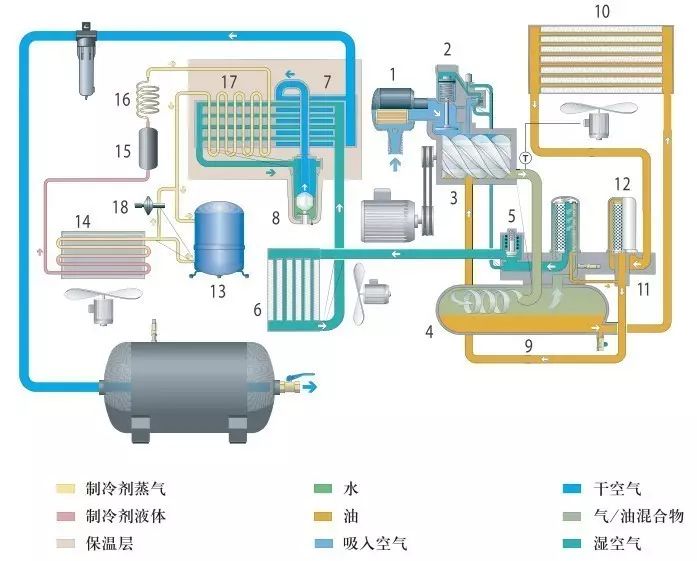

İçinde oil-injected screw compressors, large volumes of lubricating oil are injected during the compression process to reduce temperature and friction. This creates an oil-air mixture, which is then routed through the oil separator. The purpose of this separator is to extract oil from compressed air before discharge.

Eğer oil separator element fails, the oil separation efficiency drops, leading to oil carryover, which increases oil consumption and potentially damages equipment.

⚠️ Industry Standard: After separation, the oil content in compressed air should not exceed 3 ppm. Anything higher is considered excessive oil consumption or “oil carryover.”

2. Common Oil Separator Failures and Their Impact

a. Clogged Oil Separator Element

- Symptoms: High motor current, increased pressure, potential motor overload.

- Causes: Prolonged use without replacement, poor air quality.

- Solution: Monitor pressure differential; replace the element when the pressure difference reaches 0.08 MPa.

b. Damaged Oil Separator Element

- Symptoms: Severe oil consumption, visible oil in air tanks and pipelines.

- Causes:

- Delayed replacement

- Low-quality separator elements

- Improper installation damaging the element

- Solution: Replace with high-quality components and follow proper installation procedures.

c. Burnt Oil Separator Element

- Symptoms: Carbonized filter mesh, burnt separator casing.

- Causes:

- Poor-quality lubricant or separator element

- Lack of proper grounding, causing static ignition

- Solution: Use quality lubricants and ensure grounding during installation.

d. Poor Separation Efficiency

- Symptoms: High oil content in compressed air damaging downstream equipment.

- Causes: Low-quality separator elements or installation errors.

- Solution: Replace with certified separator elements and follow proper assembly steps.

3. Additional Causes of High Oil Consumption

Even if the oil separator is functioning properly, the following issues can also lead to excessive oil use:

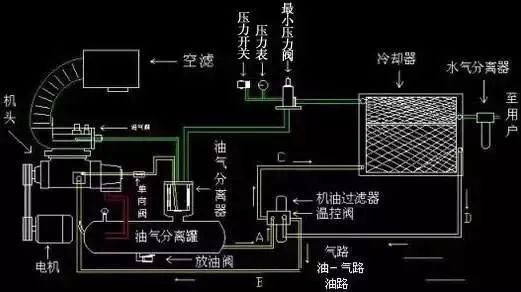

a. Minimum Pressure Valve Failure

- Effect: Causes low internal pressure during startup, increasing oil mist velocity and separator load.

- Solution: Inspect and replace the minimum pressure valve if leakage or premature opening occurs.

b. Use of Low-Quality Lubricating Oil

- Effect: At high temperatures, low-grade oil forms smaller particles (<0.01μm) that separators can’t capture.

- Solution: Seçin premium lubricants and control operating temperatures.

c. Poorly Designed Oil-Air Separator Tank

- Effect: Ineffective initial separation, high oil mist concentration before reaching the separator.

- Solution: Upgrade to a well-designed tank or consult the manufacturer for design improvements.

d. Overfilling Lubricating Oil

- Effect: Excess oil is carried away with compressed air.

- Solution: After shutdown and pressure release, drain to the correct oil level.

e. Faulty Oil Return Check Valve

- Effect: Backflow of oil into the separator during shutdown, causing oil to be expelled with air during next startup.

- Solution: Clean or replace the check valve to restore proper one-way flow.

f. Improper Oil Return Pipe Installation

- Effect: Oil fails to return to the compressor head and gets carried away with the air.

- Solution: Adjust pipe depth to 1–2 mm from the oil separator bottom with a slanted tip.

g. High Air Demand / Low Operating Pressure

- Effect: Continuous high-load operation below rated pressure increases oil mist flow and separator burden.

- Solution: Use a separator suited for low-pressure applications, or balance air demand and supply.

h. Clogged Oil Return Line

- Effect: Blockages prevent oil return, causing it to be carried away with air.

- Solution: Fully disassemble and clean the oil return line, check valve, and filter.

Son Düşünceler

If you’re experiencing unexplained oil consumption in your vidalı hava kompresörü, consider not just the oil separator element but the entire oil circuit and air system design. Regular maintenance, proper installation, and the use of high-quality components are essential to minimizing oil loss and maximizing equipment lifespan.

For more expert tips on maintaining your compressor system, visit our Maintenance & Troubleshooting section.