In modern industrial production, screw air compressors have become indispensable for powering tools, machinery, and processes across various sectors. While a compressor’s rated or design air delivery might look sufficient on paper, users often experience lower actual air output during operation.

So, what causes this gap between design capacity and actual air delivery? Let’s explore the internal mechanisms of a screw compressor and identify the key factors that affect its performance.

🌀 Understanding the Working Principle of a Screw Air Compressor

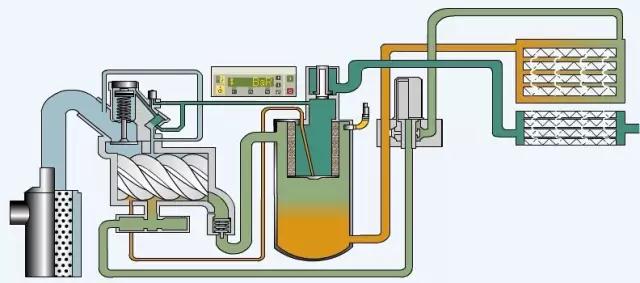

A rotary screw air compressor compresses air through a continuous rotary motion involving two intermeshing rotors: a male (driving) and female (driven) rotor. Here’s a brief breakdown of the cycle:

- Suction: As the rotors rotate, the cavity between them expands and draws in atmospheric air through the intake port.

- Compression: Once sealed from the inlet, the air is compressed as the cavity volume reduces due to rotor meshing.

- Discharge: When the compressed air reaches the outlet port, it is discharged into the piping system.

This process is continuous and depends heavily on rotor geometry, speed, and operating conditions.

🔩 Design Factors Affecting Rated Air Delivery

The theoretical air delivery of a screw compressor is determined by:

- Rotor diameter

- Rotor length

- Rotational speed (RPM)

- Helix angle (lead and twist)

- Internal clearances

A well-designed compressor will optimize these parameters for high output and energy efficiency.

⚠️ Why Actual Air Delivery May Be Lower Than Designed

Despite good design, real-world air output often falls short. The most common reasons include:

1. Internal Air Leakage

There’s always a small clearance gap between the rotors and casing to avoid metal contact. This gap causes air leakage, especially as pressure builds during compression. If the sealing edges (e.g., sealing teeth or grooves) become worn, leakage increases significantly, reducing actual air output.

✅ Tip: Schedule periodic rotor inspections and overhaul to maintain sealing performance.

2. Suction Air Conditions

Screw compressors are positive displacement machines—they draw in a fixed air volume per cycle. However, if inlet air temperature is high, the air density is lower, which means less mass of air is compressed, reducing output.

✅ Solution: Ensure proper ventilation and avoid hot intake environments.

3. Poor Cooling Performance

Heat is a byproduct of compression. If cooling systems (oil or water) aren’t working properly:

- Rotor and casing temperatures rise

- Air expands during intake due to radiant heat

- Less air is drawn in

Baldor screw compressors use advanced oil-cooled rotors and water-cooled housings to minimize this issue.

4. Clogged Filters

Dirty or clogged air filters and oil separators create airflow resistance, which reduces intake efficiency and restricts output.

✅ Solution: Replace air filters and separator elements as per the maintenance schedule.

🧰 Design vs. Reality: How to Bridge the Gap

While your compressor may be well-designed, real-world conditions can dramatically affect air delivery. Here’s how you can ensure performance stays close to rated values:

- Regularly inspect seals and clearances

- Monitor inlet air temperature

- Maintain cooling systems

- Replace filters on time

- Use compressors in well-ventilated, clean environments

✅ Conclusion

Understanding the reasons behind lower actual air delivery helps you optimize performance, reduce downtime, and extend the life of your compressor. At Baldor, we offer expertly designed screw air compressors along with proactive service to help customers maintain maximum efficiency.