Content of energy-saving diagnosis service:

According to the deployment of industrial energy-saving diagnostic services in 2021, the energy-saving diagnostic services for enterprises’ major processes, key energy-using systems, key technologies and equipment, energy management systems and other aspects include

(1) Energy-saving diagnosis of key industries. Focus on iron and steel, non-ferrous, petrochemical, chemical, building materials and other key industries, the full implementation of energy-saving diagnosis.

(2) Energy-saving diagnosis for small and medium-sized enterprises. Focus on small and medium-sized industrial enterprises with an annual comprehensive energy consumption of less than 5,000 tons of standard coal and a relatively weak energy management base, and carry out in-depth energy-saving diagnosis.

(3) Energy-saving diagnosis of key energy-using equipment. For transformers, motors, fans, air compressors, pumps, boilers and furnaces and other key energy-using equipment, assess the level of energy efficiency and the actual operation of the equipment, analyze the potential for the promotion and application of advanced energy-saving technologies and equipment, and carry out special energy-saving diagnosis.

(4) Regional centralized energy-saving diagnosis. Encourage the implementation of full-coverage energy-saving diagnosis of enterprises in industrial parks and industrial clusters, and explore new models of centralized, bulk and systematic energy-saving diagnosis services.

(5) Diagnostic tracking service. Strengthen the tracking service, encourage return visits to enterprises receiving industrial energy-saving diagnostic services in 2019 and 2020, identify the proposed implementation of energy-saving transformation measures and progress, etc., and systematically evaluate the effect of energy-saving transformation.

Energy saving, speak with data

In the manufacturing industry, the electricity consumption of production accounts for up to 70% of the electricity consumption of the whole plant, and the air compressor system accounts for 40% of the electricity consumption of production, so energy saving is urgent.

In the digital era, enterprise management “speak with data, make decisions with data, manage with data, and innovate with data” has become an immediate need.

Whether the air compressor is energy-saving or not, the power consumption of the station will tell you, and the bill of the national power grid will tell you, energy-saving, using data to speak.

Using Grade 1 energy-efficient air compressors

Baldor is one of the earliest air compressor manufacturers in China to adopt intelligent permanent magnet frequency conversion technology, and its technology is at the international leading level. It is also the drafting unit of many air compressor technical standards in China, and its products have won many energy-saving technology awards, and it has been selected in the energy-saving recommended directory of the Ministry of Industry and Information Technology for many years.

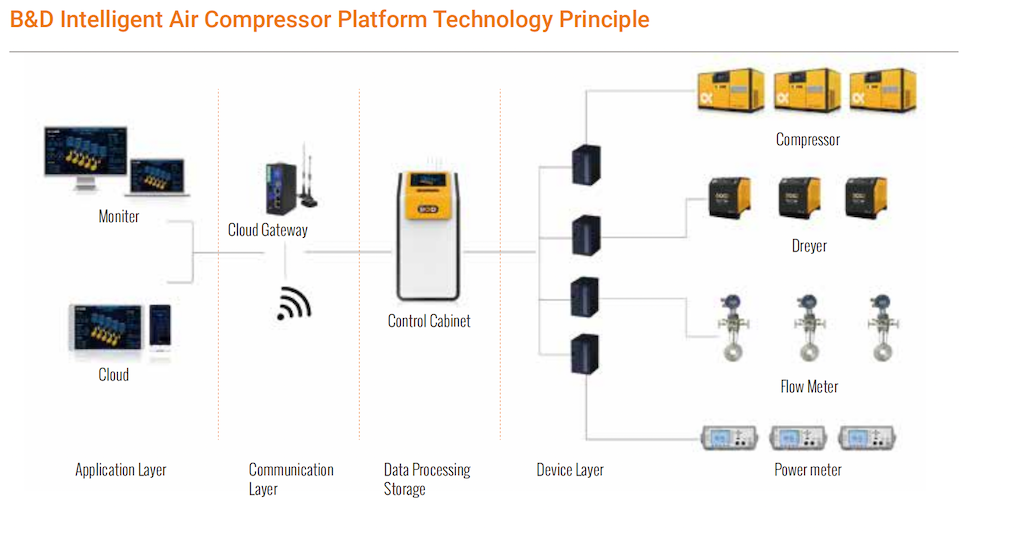

Program intelligent energy-saving air compressors can all be digitally managed by Program Cloud System.

With ultra-low specific power, ultra-quiet and more environmental friendly, the comprehensive performance and energy-saving level of the national Grade 1 energy-efficiency certified Program permanent magnet screw compressor far exceeds those of Grade 2 and 3 energy-efficient air compressors, providing users with powerful and stable compressed air production power and maximizing energy-saving and production benefits.

The Ministry of Industry and Information Technology promotes industrial energy-saving diagnosis, energy saving has become an immediate need, and digital air compressor stations have great potential!

According to the new GB19153-2019 national standard, taking the Program 160KW pressure 0.7MPa air-cooled screw machine as an example, the specific power of the Program Grade 1 energy efficiency standard is 5.9, a certain Grade 2 is 6.4, and a certain Grade 3 is 6.9.

According to the standard value of energy efficiency, Program Grade 1 energy efficiency is 7.8% more energy-efficient than Grade 2 and 14% more energy-efficient than Grade 3. The cost of electricity is (6.9-5.9)×25×5000=125000RMB.

Use of digital intelligent air pressure station

Traditional air pressure stations rely heavily on manual management, manual switching on and off, manual meter reading, which is time-consuming, laborious and untimely, with high risk of downtime.

By combining multiple air compressors together through AI data technology, Baldor has formed a more intelligent air pressure station room with many digital functions such as constant pressure, remote management, automatic meter reading and intelligent joint control, etc. Energy saving speaks with data, changing the situation of traditional air pressure station room with high energy consumption and high maintenance cost.

Baldor digital intelligent air compressor station has been applied to manufacturing users in many industries, saving time and effort, with comprehensive functions, helping users to save energy and cut costs in factories and opening up the era of digital energy management.